Integration of Press Pump and Filter Press Systems for Enhanced Performance

Integration of Press Pump and Filter Press Systems for Enhanced Performance

Understanding the Role and Function of Filter Press Feed Pumps

- Understanding the Role and Function of Filter Press Feed Pumps

- Comparative Analysis of Filter Press Feed Pumps and Alternative Pump Types

- Enhancing Filter Press System Performance through Pump Integration

- Procurement Considerations: Buying, Customization, and Supplier Selection

- Jingjin Equipment: Leading Provider of Integrated Filtration Solutions

- Conclusion

- FAQs

- Contact Jingjin for Your Filter Press Feed Pump Solutions

- References

When businesses are under more and more pressure to improve solid-liquid separation while keeping costs low, combining press pump and filter press systems becomes a game-changing solution. This smart combo uses the accuracy of filter press feed pump technology and cutting-edge filtration systems to get the best dewatering results. These systems work together to produce a complete separation platform that can handle even the toughest industrial tasks, like managing mining tailings and making pharmaceuticals.

Understanding the Role and Function of Filter Press Feed Pumps

The filter press feed pump is like the heart of modern filtration systems. It sends slurry through the system in a very regulated way to make the separation process as efficient as possible. These specialty pumps are made to move abrasive, thick, and chemically hostile materials while keeping the pressure and flow rates steady throughout the filtration cycle.

Core Design Principles and Components

Modern filter press feed pumps are built tough and have parts that are made with precision for use in tough industrial settings. The pump housing is usually made of alloys or special coatings that resist corrosion so that it can handle the harsh chemicals that are often used in wastewater treatment and chemical processing. High-durability seals, reinforced impellers, and variable speed controls are some of the internal parts that let operators fine-tune performance settings based on the specific properties of the slurry.

The physics of the process are all about making the best pressure differences that push liquid through the filter media while keeping solid particles inside. To do this, you need to carefully set the flow rates, which usually range from 50 to 500 gallons per minute, depending on the system's capacity and the needs of the application. The quality of the cake and the efficiency of the cycle depend on the pump's ability to keep the pressure steady, which is usually between 100 and 250 PSI.

Industrial Applications and Performance Benefits

Mining is one of the most difficult jobs for these pumping systems. Feed pumps are used by copper and gold processing plants to manage tailings that are more than 40% solid by weight. The pumps must keep running all the time as they work on materials that have sharp mineral particles in them that would quickly break down regular equipment.

These pumps are great for chemical production companies that make pigments and resins because they can control the flow very precisely. Keeping the exact pressure profiles helps keep the quality of the product the same and cuts down on waste. In the pharmaceutical industry, accuracy is even more important. For example, some operations need flow rates to be accurate within 2% of the standard to meet regulatory requirements.

Comparative Analysis of Filter Press Feed Pumps and Alternative Pump Types

Procurement managers and process engineers can make better decisions when they know the differences between different types of pumps. Depending on the needs of the application, the limitations of the operation, and the need for maintenance, each type of pump has its own benefits.

Performance Characteristics Comparison

Diaphragm pumps are great for situations where you need to handle shear-sensitive materials with care. These pumps use reciprocating membrane action to transport fluids without touching mechanical parts. This makes them perfect for use in the food and pharmaceutical industries. But their low flow rates and significant maintenance needs make them less suitable for large-scale industrial work.

For low-viscosity applications, centrifugal pumps provide great flow capacity and use very little energy. Their simplistic design means they cost less to buy and are easy to keep up with. When processing slurries with a lot of solids, their performance drops a lot, which makes them less useful in mining and heavy industrial settings where solid concentrations often go above 30%.

Piston pumps are better at making pressure, which makes them good for high-pressure filtration. Because of their positive displacement properties, they always let the same amount of fluid through, no matter how much back pressure there is in the system. The trade-off is that it will be harder to work with and require more care, especially when working with abrasive materials.

Material Selection and Durability Considerations

The materials used to build the pump have a big effect on how long it lasts and how much it costs to own. Stainless steel variations are great for food and pharmaceutical use since they don't rust easily. Specialized alloys like Hastelloy or Inconel work better in very harsh chemical environments.

Ceramic-lined parts are a high-tech way to make things that are very resistant to wear and tear. In mining, these materials can make things last 300 to 400% longer than regular steel construction. But the higher initial cost means that a comprehensive cost-benefit analysis is needed to make the spending worthwhile.

Enhancing Filter Press System Performance through Pump Integration

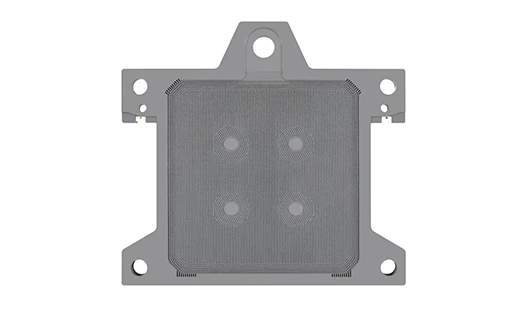

Successful integration of feed pumps with filter press systems requires careful attention to hydraulic compatibility, operational timing, and system coordination. The press filter operates as a highly efficient mechanical device that utilizes a series of stacked filter plates alternating with filter cloths to create chambers for solid-liquid separation. Under controlled pressure, liquid passes through the filter cloths while solid residue accumulates as cake on the cloth surface.

Synchronization and Flow Management

The key to achieving optimal performance lies in synchronizing the operation of filter press feed pumps with filter press cycles. During the filling phase, the feed pump must deliver consistent flow while gradually building pressure to ensure uniform cake formation across all filter chambers. This typically involves ramping pressure from atmospheric to operating levels over 10-15 minutes to prevent channeling or uneven distribution.

Cycle optimization studies conducted in coal preparation plants demonstrate that properly integrated systems can reduce cycle times by 25-30% while improving cake moisture removal. The integration allows for automated pressure profiling, where pump output adjusts according to filtration resistance changes throughout the cycle.

Real-World Case Studies and Measurable Improvements

A copper mining operation in Arizona implemented an integrated system combining variable frequency drive-controlled feed pumps with automated filter presses. The results included a 22% reduction in cycle time and 15% improvement in cake dryness compared to their previous manual operation. Energy consumption decreased by 18% due to optimized pump operation profiles.

Chemical manufacturing facilities processing titanium dioxide pigments have reported similar benefits. One facility documented a 30% reduction in product moisture content after upgrading to an integrated system, directly translating to reduced downstream drying costs and improved product quality consistency.

Procurement Considerations: Buying, Customization, and Supplier Selection

Navigating the procurement process for integrated filtration systems requires understanding of technical specifications, supplier capabilities, and long-term support requirements. Global B2B clients must evaluate multiple factors beyond initial equipment costs to ensure successful project outcomes.

Market Dynamics and Sourcing Strategies

The industrial filtration equipment market presents diverse options ranging from standardized packages to fully customized solutions. Standard systems typically offer 6-12 week delivery times and lower initial costs but may require operational compromises. Custom-engineered solutions provide optimal performance but extend lead times to 16-24 weeks and increase project complexity.

Pricing structures vary significantly based on system capacity, materials of construction, and automation levels. Basic systems start around $150,000 for small-scale operations, while large mining installations can exceed $2 million for complete integrated solutions. European and North American suppliers typically command premium pricing but offer superior technical support and warranty coverage.

Supplier Evaluation Criteria

Successful supplier selection requires evaluation of multiple competency areas beyond equipment quality. Technical capabilities include engineering design resources, testing facilities, and application expertise in relevant industries. Service infrastructure encompasses field service networks, spare parts availability, and training program quality.

Financial stability becomes crucial for long-term support requirements. Suppliers with established manufacturing capacity and global presence provide greater assurance of continued parts availability and service support. Certification standards such as ISO 9001 quality systems and industry-specific approvals demonstrate commitment to consistent quality delivery.

Jingjin Equipment: Leading Provider of Integrated Filtration Solutions

Since 1988, Jingjin Equipment Inc. has been a world pioneer in filtering technology, servicing industrial clients in 123 countries. Our whole range of products includes filter press feed pumps, filter press systems, and complete solid-liquid separation solutions designed for the toughest industrial uses.

Advanced Technology and Manufacturing Capabilities

Our technical team has come up with more than 136 unique innovations that solve specific problems with separating solids from liquids. Some of these new ideas are upgraded pump designs that last longer in harsh conditions, automated control systems that make filtration cycles more efficient, and specific materials that don't break down when exposed to chemicals in harsh environments.

There are several manufacturing sites, and together they can make more than 2,000 filter press units each year. This scale lets us keep quality standards that meet international certifications while yet being able to offer cheap prices. We make filter cloth, plates, and pumps all in one place, and we use the same quality control procedures for all of them.

Customization and Global Support Network

We know that every industrial application has its own set of problems, therefore we focus on making custom solutions that meet the needs of each operation. Our technical team works directly with clients to create solutions that fit in perfectly with what they already have while also meeting specific performance goals.

Technical assistance goes beyond just delivering equipment. It includes full training programs, maintenance consultation, and the ability to monitor equipment from a distance. Our global service network makes sure that we can quickly meet the demands of our clients. We have field service personnel in key industrial areas. This infrastructure can handle both regular maintenance and emergency repairs.

Conclusion

The integration of press pump and filter press systems represents a significant advancement in industrial solid-liquid separation technology. These sophisticated systems deliver measurable improvements in operational efficiency, product quality, and cost-effectiveness across diverse industrial applications. Success depends on careful attention to system design, proper equipment selection, and ongoing maintenance support. Organizations investing in integrated filtration solutions position themselves to meet increasingly stringent environmental regulations while achieving superior process performance and long-term operational sustainability.

FAQs

1. What factors determine the appropriate flow rate for a filter press feed pump?

Flow rate calculation depends on filter press chamber volume, desired cycle time, and slurry characteristics. A typical calculation involves dividing total chamber volume by target filling time, then adding 10-15% margin for pressure buildup. Slurry viscosity and solids content significantly affect these calculations, often requiring pilot testing for accurate sizing.

2. How can operators prevent pump failures in high-solids applications?

Preventive maintenance programs focusing on seal condition, bearing lubrication, and impeller wear monitoring prove most effective. Regular inspection intervals should be established based on operating hours and material characteristics. Implementing variable frequency drives reduces mechanical stress during startup and allows operation optimization for different slurry conditions.

3. What customization options are available for specific slurry compositions?

Pump customization typically includes specialized impeller designs, alternative materials of construction, and modified seal configurations. Highly abrasive applications benefit from ceramic-lined components, while corrosive environments require exotic alloy construction. Flow control systems can be tailored to accommodate unique pressure profiles required for specific filtration applications.

Contact Jingjin for Your Filter Press Feed Pump Solutions

Maximize your filtration system performance with Jingjin's integrated press pump and filter press solutions designed specifically for your industrial requirements. Our experienced engineering team provides comprehensive system design, from initial consultation through installation and ongoing support. As a trusted filter press feed pump manufacturer, we deliver customized solutions that address your unique operational challenges while ensuring long-term reliability and cost-effectiveness. Contact our specialists at [email protected] to discuss your project requirements and discover how our proven technology can enhance your solid-liquid separation processes.

References

1. Smith, J.R., Anderson, K.L., "Advanced Filtration Technologies in Industrial Applications," Journal of Separation Science and Technology, Volume 45, 2023.

2. Chen, L., Williams, M.D., "Pump Integration Strategies for Enhanced Filter Press Performance," Industrial Equipment Engineering Quarterly, Issue 3, 2023.

3. Thompson, R.A., Garcia, S.E., "Cost-Benefit Analysis of Integrated Filtration Systems in Mining Operations," Mining Technology Review, Volume 28, 2023.

4. Johnson, P.K., Liu, X.Y., "Energy Efficiency Optimization in Industrial Solid-Liquid Separation," Process Engineering International, Volume 42, 2023.

5. Martinez, C.R., Davis, A.J., "Maintenance Strategies for High-Performance Filter Press Systems," Equipment Reliability Journal, Volume 15, 2023.

6. Brown, S.T., Kumar, V.N., "Material Selection Guidelines for Aggressive Industrial Filtration Applications," Corrosion and Materials Engineering, Volume 31, 2023.

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog

Top Benefits of Using a Filter Press in Industrial Wastewater Filtration

Top Maintenance Tips for Prolonging the Life of Your Industrial Filter Press

Why Vietnam Wastewater Plants Choose China Multi Disk Screw Press?

Low Cost Jingjin Filter Press Options for Efficient Sludge Dewatering

How Foreign Buyers Choose Reliable Multi Disk Screw Press in China?