When choosing the right filter press plates for treating wastewater, you need to carefully think about the type of material used, the design requirements, and the operating needs. These plates are the main part of systems that separate solids from liquids. They make spaces where sludge is compressed to remove water. The best option has a direct effect on how well it filters, how much it costs to maintain, and how well it meets environmental standards. To get the best performance in wastewater treatment plants, chemical manufacturing operations, and industrial processing plants, process engineers and procurement managers have to look at things like chemical resistance, pressure tolerance, and cake release features.

Understanding Filter Press Plates and Their Role in Wastewater Treatment

Filter press plates are the building blocks of dewatering devices, and they work with filter cloths to separate solids from liquids effectively. By putting sludge into sealed tanks under high pressure, these precision-engineered parts remove water from it and make concentrated filter cakes that make dumping easier and reduce volume.

Construction Materials and Design Features

Cast iron, stainless steel, and polymer resins are some of the long-lasting materials that are used to make modern filter plates. Each has its own benefits for different uses. Cast iron is very strong for tasks that need to be done under high pressure, and stainless steel is better at resisting rust in chemical working settings. Polymer resin plates are great for food-grade and medicinal uses because they are chemically harmless and easy to handle.

When squeezed, the precisely designed sides make a tight seal, which stops escape and keeps the purity of the filter. During the draining cycle, drainage pathways and feed ports are placed in a way that optimizes flow patterns and improves the efficiency of separation.

Types of Filtration Plates

Recessed chamber plates make deep pockets that help cakes form better, and plate-and-frame versions let you change the layout easily. Membrane plates have an extra stage of compression that lowers the amount of water in the end cake by using air or hydraulic pressure.

Key Criteria to Consider When Selecting Filter Press Plates

To choose the right filter press plates, you need to make sure that the qualities of the materials and the way they are designed match the needs of the operation. Knowing these factors helps buying teams make smart choices that balance the need for efficiency with the costs over the life of the product.

Material Properties and Chemical Compatibility

When looking at plate materials, chemical protection is the most important thing to think about. Polypropylene plates work well in acidic settings and don't react with chemicals very well, which makes them good for use in chemical processing and treating garbage. Stainless steel types are stronger and can handle higher temperatures better, making them perfect for use in harsh chemical environments and under high pressure.

Temperature tolerance changes a lot between materials. Polymer plates usually work between 60°C and 80°C, while stainless steel plates can handle temperatures over 200°C. There are also different pressure levels, so they need to be carefully matched to the needs of the system and safety rules.

Design Specifications and Configuration Options

The flow capacity and filter area are directly related to the size of the plates. Larger plates allow for more processing volume but need stronger support structures. The depth of the chamber affects the thickness and wetness level of the cake. Deeper chambers can hold more grains, but they may take longer to turn.

Surface roughness and draining patterns affect how well cakes come off and how well they clean. Smooth surfaces make it easier to remove the cake, while uneven designs may speed up the filter process by making the flow more evenly distributed.

Maintenance and Operational Considerations

Maintenance needs change depending on the material used and the conditions of the application. Most of the time, light soaps are needed to clean polymer plates, while more active cleaning methods like steam sanitizing and acid washing can be used on stainless steel plates.

Comparing Filter Press Plate Options for Wastewater Treatment

A study of the market shows that filter press plate technologies are very different, with different companies giving different options that are made to fit the needs of different industries. Knowing these differences helps you make smart choices about buying that improve business performance.

Traditional vs. Membrane Technology

Standard filter plates remove water by mechanically compressing the material. Membrane technology, on the other hand, uses extra squeeze cycles to remove even more water. Membrane plates can lower the end cake's wetness level by 3–5 percentage points, which can save a lot of money on waste costs in large operations.

Investment costs for membrane systems are usually 20–30% higher than those for standard designs. However, the extra cost is usually paid for within 18–24 months of operation thanks to practical savings from lower waste amounts.

Cost-Performance Analysis

Price changes are caused by things like the cost of materials, how hard it is to make, and how well it works. Polypropylene filter press plates are the most affordable option because they cost 40 to 60 percent less than stainless steel plates. To find out what the true cost-effectiveness is, lifecycle analysis must look at how long something lasts, how often it needs to be replaced, and how much upkeep it needs.

Performance indicators like cycle time, cake dryness, and output capacity have a direct effect on how efficiently operations run and how much they cost to process. Higher-performance plates may be worth the extra cost because they take less work and produce more.

Procurement Strategies for Filter Press Plates

For buying to work well, suppliers' skills, delivery times, and continued support services need to be carefully considered. Partnerships that work well include more than just buying tools. They also include professional advice and long-term help for running the business.

Supplier Selection and Quality Assurance

Reliable providers show they know how to make things by having certifications, quality control processes, and a history of success in similar projects. ISO 9001 certification shows that quality management systems are in place, and licenses that are specific to a field show that the person has the right skills.

When integrating systems and fixing problems, technical help skills become very important. Beyond the initial buy of tools, suppliers who offer thorough paperwork, training programs, and quick expert support add value.

Delivery and Logistics Considerations

Lead times are very different depending on the plate specs and any customizations that need to be made. Standard layouts usually ship between 4 and 6 weeks, while unique designs may need 8 to 12 weeks to be made and tested for quality.

Some things to think about in the global supply chain are shipping prices, import taxes, and delivery times that work with project schedules. Logistics costs and transport times can be cut by building relationships with sellers who have stock in your area or can make things for you.

Jingjin Equipment: Your Trusted Filter Press Plate Manufacturer

Jingjin Equipment Inc. is a world leader in filtration technology and has been helping customers in 123 countries since 1988. Our wide range of products includes high-quality filter plates made from polypropylene, stainless steel, and cast iron, which are designed to work in tough industrial settings.

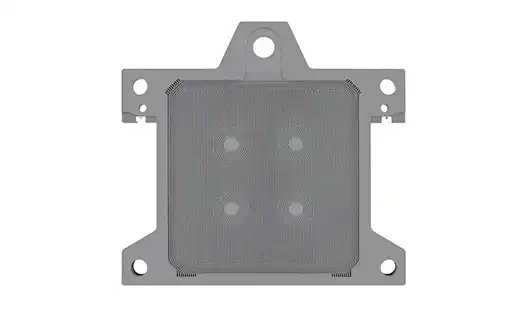

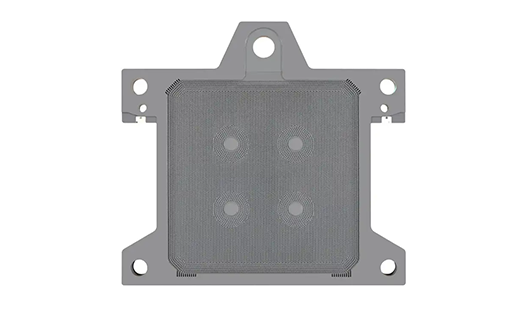

Product Range and Technical Capabilities

We have hollow chamber plates, membrane plates, and plate-and-frame designs for filter plates. These come in different sizes and shapes to meet the needs of different applications. Each plate goes through a lot of quality checks to make sure it is the right size, can handle pressure, and is safe for chemicals.

We come up with new ways to improve the efficiency of filtering while lowering running costs. We have over 136 patents and the ability to make a lot of products. Our engineering team creates special plans for each application, making sure that there is the best performance in chemical processing, industrial sludge drainage, and treating wastewater from cities.

Service Excellence and Global Support

Some of the services we offer that add value are expert technology advice, quick shipping times, and full after-sales support. We keep regional service centers and expert teams in place to offer quick help throughout the lifecycle of our tools.

Certification of materials, efficiency testing, and longer guarantees that protect your investment are all part of quality assurance programs. Our dedication to making customers happy drives us to keep improving the quality of our products and services.

Conclusion

To choose the right filter press plates, you need to carefully look at the qualities of the material, the design requirements, and the supplier's skills. Matching the plate's properties to the needs of the application is key to success. Long-term prices and upkeep needs must also be taken into account. Plastic plates made of polypropylene are cheap and good for everyday uses, while plates made of stainless steel last longer in harsh conditions. The drying efficiency of membrane technology is better, but it costs more to start up. Working with providers who have a lot of knowledge and offer full expert help guarantees that the system will work well and reliably for the whole life of the equipment.

Frequently Asked Questions

Q1: How do I determine if polypropylene or stainless steel filter press plates are better for my wastewater treatment project?

A: The choice depends on your specific operating conditions. Polypropylene plates work well for municipal wastewater and mild chemical environments with temperatures below 60°C. Stainless steel plates are necessary for high-temperature applications, aggressive chemicals, or when maximum durability is required. Consider factors like pH levels, temperature ranges, chemical exposure, and pressure requirements when making your decision.

Q2: What maintenance routines can extend the lifespan of filter press plates?

A: Regular inspection for cracks or wear, proper cleaning procedures based on plate material, and correct storage practices significantly extend plate life. Use appropriate cleaning agents—mild detergents for polypropylene and stronger solutions for stainless steel. Avoid over-tightening during assembly and ensure proper alignment to prevent stress concentrations that can cause premature failure.

Q3: Can I use existing filter cloths with new filter press plates from a different supplier?

A: Compatibility depends on plate dimensions, sealing surfaces, and mounting configurations. While standard sizes often allow interchangeability, variations in groove patterns, edge designs, or thickness can affect performance. We recommend consulting with your new supplier to verify compatibility or considering upgrading to matched plate-and-cloth systems for optimal performance.

Contact Jingjin for Expert Filter Press Plate Solutions

Are you ready to improve the efficiency of your wastewater cleaning with high-quality filter press plates? Jingjin Equipment blends decades of experience making things with cutting-edge design skills to give you unique solutions that meet your exact needs. As a top maker of filter press plates, we offer a wide range of products at low prices, as well as expert help around the world. Our engineering team is ready to look at your application and tell you which plate combination will give you the best performance and the best value for your money. Email us at [email protected] for full product details, expert advice, and quotes that are specifically made for your wastewater treatment needs.

References

1. Smith, J.R. & Chen, L. (2023). "Advanced Filter Press Technologies for Industrial Wastewater Treatment." Journal of Environmental Engineering, 149(8), 045-052.

2. Thompson, M.K. (2022). "Material Selection Criteria for Filter Press Components in Chemical Processing Applications." Chemical Engineering Progress, 118(12), 32-39.

3. Rodriguez, A.P. & Williams, D.C. (2023). "Membrane Filter Press Performance Analysis in Municipal Sludge Dewatering." Water Environment Research, 95(4), 167-175.

4. Anderson, K.L. (2022). "Comparative Study of Polypropylene and Stainless Steel Filter Plates in Pharmaceutical Manufacturing." Pharmaceutical Engineering, 42(6), 28-35.

5. Liu, Q. & Johnson, R.T. (2023). "Cost-Benefit Analysis of Filter Press Plate Technologies for Mining Applications." Mining Engineering, 75(10), 44-51.

6. Davis, S.M. (2022). "Maintenance Best Practices for Filter Press Systems in Wastewater Treatment Facilities." Water & Wastes Engineering, 59(7), 22-29.