High Quality Filter Press Plates for Mining Industry: Choosing Durable and Efficient Filter Press Components

High Quality Filter Press Plates for Mining Industry: Choosing Durable and Efficient Filter Press Components

What Makes a Mining-Grade Filter Press Plate Different?

- What Makes a Mining-Grade Filter Press Plate Different?

- How Filter Press Plates Impact Mining Dewatering Performance?

- How to Choose the Right Filter Press Plates and Supplier for Mining Projects?

- Conclusion

- FAQs

- Mining Filter Press Plate Manufacturers and Suppliers for Tailings Dewatering | Jingjin

- References

A high‑quality Filter Press Plate is the backbone of every mining filtration system. In tailings and concentrate dewatering, plates carry the mechanical load, hold the chambers that shape the cake, support the filter cloth, and endure constant high pressure and abrasion. When plates are engineered correctly, they deliver tight sealing, high filtration pressure, and consistent cake formation, which leads to drier tailings, higher water recovery, and lower disposal costs. When they are poorly designed or mismatched to the slurry, operations face cracked plates, leakage, uneven cakes, and unplanned downtime. In a mining environment where every hour of stoppage can mean lost production and higher risk in tailings management, choosing durable and efficient press components is a strategic decision, not a simple purchase. Understanding how plates are built, which designs suit mining, and what to look for in a long‑term supplier helps engineers and project managers make better choices.

What Makes a Mining-Grade Filter Press Plate Different?

Core Function of Plates in High-Pressure Dewatering

The Filter Press Plate is a key component of the press system, serving as the rigid frame that holds the filter cloth and creates the chambers where solid‑liquid separation takes place. In mining, these plates must form a precise seal when compressed by the hydraulic system, so slurry stays inside the chambers and filtrate exits through internal channels. Under high feed pressure, plates endure repeated mechanical stress, abrasive contact with mineral particles, and thermal variations from process conditions.

Constructed from durable materials such as cast iron, stainless steel, or polymer resins, plates used in tailings and concentrate dewatering have to balance strength, weight, and chemical resistance. In modern installations, high‑strength polypropylene plates are widely used because they offer good resistance to corrosion, relatively low weight for easier handling, and flexibility under stress. In some very harsh services, stainless steel or cast‑iron designs are still selected for specific duties.

Material Choices for Abrasive and Corrosive Mining Slurries

We offer a wide range of filter plates designed to meet the diverse needs of clients in mining and other industries. These plates are made from high‑quality materials such as polypropylene, stainless steel, and cast iron, ensuring durability and long‑lasting performance in demanding filtration applications. For abrasive mining tailings, impact‑resistant polypropylene plates with reinforced ribs and thick edges are commonly specified. For corrosive leach solutions or metallurgical processes, stainless steel or special polymers may be chosen to resist attack and preserve long‑term integrity.

In mining operations handling iron ore, copper, gold, coal, or other minerals, plate materials are evaluated using key criteria:

- Mechanical strength under operating pressure and temperature

- Resistance to wear from sharp or dense particles

- Resistance to process chemicals, pH variations, and cleaning agents

- Dimensional stability over thousands of press cycles

When these factors are addressed at the specification stage, plates maintain tight sealing and geometric accuracy, which supports stable filtration and consistent cake thickness.

Plate Designs Used in Mining and Mineral Processing

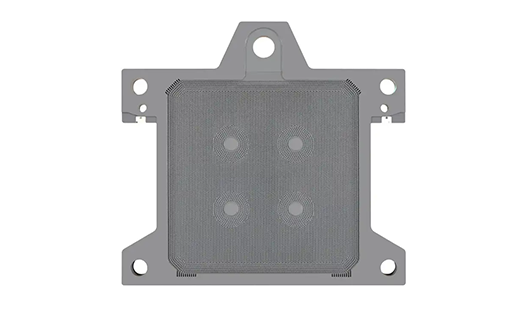

Available in various sizes and configurations, mining-grade Filter Press Plates often include recessed chamber plates and membrane plates. Chamber plates create a cavity for cake formation and are widely used for tailings and concentrate dewatering because they are simple, robust, and easy to maintain. Membrane plates add a flexible membrane that can be pressurised after filling, squeezing the cake to further reduce moisture content and shorten cycle times.

In high‑throughput mining plants, engineers select plate sizes and types based on:

- Required cake thickness and solids content

- Target moisture level for tailings or concentrates

- Available filtration pressure and cycle length

- Space constraints in the filter building

Each plate is carefully engineered for optimal performance, offering superior cake release, easy maintenance, and improved filtration efficiency. This engineering detail, including drainage pattern design and feed port placement, directly influences how evenly slurry fills the chambers and how consistently cakes form across the press.

How Filter Press Plates Impact Mining Dewatering Performance?

From Tailings Slurry to Stackable Cake

Mining and mineral processing plants rely on press filtration to transform fluid slurries into stackable, low‑moisture cake. Tailings slurry or concentrate is pumped into the press, where plates and cloths work together to separate solids from water. The internal channels and surface patterns of the plates distribute slurry across each chamber. As pressure builds, water passes through the cloth and plate drainage paths, leaving solids behind as a compact cake.

Well‑designed plates ensure:

- Even slurry distribution to avoid thin or partially filled cakes

- Efficient drainage to maintain high filtration rates

- Low internal dead zones that can trap solids and reduce the active area

- Stable support for cloth, preventing wrinkles that might cause leakage paths

In tailings management, this leads to improved water recovery and more stable dry stacking or co‑disposal, which aligns with modern standards for responsible mine waste handling.

Reducing Moisture and Cycle Time in Mining Operations

Global mining case studies show that improved plate design, along with suitable filter cloth and control strategy, can significantly reduce cake moisture and cycle length. Drier cake means less weight and volume to transport or store, lower risk in tailings facilities, and better conditions for water reuse in the plant. Shorter cycles increase daily tonnage processed by each press, which can defer or eliminate the need for additional equipment.

High‑quality plates contribute to these gains through:

- Accurate chamber depth that produces uniform cake thickness

- Optimised drainage patterns that support rapid filtrate removal

- Strong support ribs that limit plate deflection under high pressure

In concentrated dewatering, such as copper or zinc concentrates, consistent moisture levels help improve handling, transport, and downstream drying. Press plates that maintain their shape and surface accuracy over time help sustain these performance levels cycle after cycle.

Minimising Downtime and Safety Risks Underground or On Site

In mining, unplanned downtime is costly and can disrupt the entire production chain. Filter Press Plate failures, such as cracking, warping, or port damage, often lead to leaks, incomplete cakes, and emergency shutdowns. High-quality Filter Press Plates with robust designs and proven manufacturing control reduce the risk of such failures.

Beyond direct downtime, plate integrity also influences safety. Leaking slurry at high pressure can create slippery floors and unexpected spray, which poses hazards to maintenance and operating staff. Solid, well‑sealed plates help contain process fluids inside the press, improving housekeeping and safety metrics around filtration areas in concentrators or tailings plants.

Operations data from modern mines shows that investing in durable, mining‑grade plates reduces the frequency of plate changeouts and emergency maintenance. This allows maintenance teams to work on planned schedules with appropriate tools and lifting equipment, rather than responding to urgent failures under time pressure.

How to Choose the Right Filter Press Plates and Supplier for Mining Projects?

Key Specification Points for Process and Project Engineers

Process engineers, tailings managers, and EPC project teams evaluating plate options for mining projects usually focus on clear technical criteria. Important questions include:

- What is the design and maximum operating pressure for the filtration stage? This defines the mechanical strength needed for each plate and the required safety margin.

- What type of slurry will be processed—tailings, concentrate, or process intermediates? Abrasive content, particle size distribution, and chemical composition guide material and design choices.

- What dryness and throughput targets must be achieved? Tailings disposal methods and concentrate logistics drive desired cake moisture and cycle times.

What operating environment will the press work in—surface plant, underground, or remote site? This influences plate size, weight, and ease of handling during maintenance.

By answering these questions early, teams can select appropriate sizes, chamber depths, and configurations such as recessed chamber or membrane plates. This helps align equipment capability with life‑of‑mine plans and evolving production needs.

Why a Complete Ecosystem Supplier Matters in Mining?

The Filter Press Plate does not work alone. It interacts with the steel frame, hydraulic system, filter cloth, feed pumps, and control logic. When different pieces come from unrelated sources, troubleshooting performance can become complex. A supplier that designs and manufactures the full press, including plates and cloth, can align all components and simplify optimisation.

Jingjin Equipment Inc., founded in 1988, is one of the world’s leading manufacturers of filter press systems, filter plates, filter cloth, and solid‑liquid separation solutions. With more than 136 patents and clients in 123 countries, Jingjin has deep experience in mining and mineral processing, municipal and industrial wastewater, chemical production, and construction dewatering. Large‑scale manufacturing capacity allows Jingjin to deliver both individual presses and full fleets with consistent quality, which matters in multi‑line concentrators or large tailings facilities.

For mining companies and EPC contractors, this ecosystem approach brings:

- Matched plates, cloth, and frames designed to work together

- Standardised spare parts and documentation across multiple sites

- Engineering support for process design, commissioning, and optimisation

- Access to a global service network for long‑term operation

Building Long-Term Reliability and Lower Total Cost of Ownership

Mining projects often run for decades. Filtration systems, including plates, must deliver not only high initial performance but also predictable life‑cycle costs. Choosing robust plate designs and a stable supplier reduces risks related to future availability of spares, engineering support, and product upgrades.

Jingjin’s value lies in its patented technology, large‑scale production capacity, full product ecosystem, global service network, and strong reliability. Ideal customers seek long‑term operational stability, high dewatering efficiency, and a supplier capable of supporting complex industrial applications worldwide. By viewing press plates as part of a strategic filtration platform instead of a consumable, mining operators can improve water recovery, reduce tailings risks, and protect production over the full life of their assets.

Conclusion

High‑quality filter press plates are central to safe, efficient dewatering in the mining industry. They shape the cake, withstand high pressure and abrasion, and support filter cloth performance. When plates are chosen with attention to material, design, and operating conditions, mining operations gain drier tailings, higher throughput, fewer plate failures, and more predictable maintenance schedules. This directly supports production goals, water management strategies, and environmental compliance.

Jingjin Equipment Inc. has supplied press systems, plates, and cloth to industrial clients in 123 countries since 1988. With 136+ patents, strong manufacturing capacity, and a complete filtration ecosystem, Jingjin helps mining companies, mineral processors, and EPC contractors design and operate robust dewatering solutions. For tailings, concentrate, or process slurry projects where uptime and performance matter, partnering with an experienced filtration specialist can protect both production and long‑term investment.

FAQs

Q1: How often should filter press plates be replaced in a mining operation?

A: Replacement intervals depend on operating pressure, slurry abrasiveness, chemical conditions, and maintenance practices. In many mines, quality plates operate reliably for several years. Regular inspections for cracks, warping, and port damage, along with monitoring of leakage and cake uniformity, help determine the right replacement schedule before failures occur.

Q2: What is the difference between chamber plates and membrane plates for tailings?

A: Chamber plates form a fixed‑volume cavity where the cake builds, offering a robust and straightforward solution for many tailings and concentrate duties. Membrane plates include a flexible diaphragm that inflates after filling to squeeze the cake, which can reduce moisture and shorten cycles. The best choice depends on target dryness, energy costs, and capital budget.

Q3: What information should I provide when requesting filter press plates for a new mining project?

A: Useful information includes ore type, tailings or concentrate description, particle size distribution, solids concentration, pH and chemical composition, desired cake moisture, required throughput, available filtration pressure, and environmental or space constraints. Sharing these details helps plate manufacturers recommend appropriate materials, plate types, and sizes tailored to your dewatering goals.

Mining Filter Press Plate Manufacturers and Suppliers for Tailings Dewatering | Jingjin

For mining companies, mineral processing plants, and EPC contractors seeking a reliable Filter Press Plate manufacturer and long‑term partner, Jingjin Equipment Inc. offers engineered plates, complete press systems, and matched filter cloths designed for heavy‑duty tailings and concentrate dewatering. By aligning plate materials, chamber design, and press configuration with your slurry characteristics and production targets, Jingjin helps improve cake dryness, boost throughput, and stabilise filtration performance. To request technical support, plate specifications, or a quotation for your mining project, contact our engineering team at [email protected] and describe your current or planned dewatering setup.

References

1. Wills, B. A., and Finch, J. “Wills' Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery.” Elsevier.

2. Society for Mining, Metallurgy & Exploration (SME). “SME Mining Engineering Handbook.” SME.

3. International Council on Mining and Metals. “Tailings Management: Good Practice Guidance for Mining Operators.”

4. European Federation of Chemical Engineering. “Solid–Liquid Filtration in the Mining and Process Industries: State of the Art.”

5. Tarleton, E. S., and Wakeman, R. J. “Solid/Liquid Separation: Equipment Selection and Process Design.” Butterworth‑Heinemann.

6. Water Research Commission. “Integrated Water and Tailings Management in the Mining Industry: Dewatering Technologies and Practices.”

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog