Understanding the Importance of Quality in Multi-Drive Screw Press Selection

The quality of a Multi Disk Screw Press is vital when it comes to guaranteeing effective and solid solid-liquid division forms. High-quality presses offer various benefits that can essentially affect a company's operations and profitability.

Key Benefits of Investing in a Quality MMulti-DriveScrew Press

- Improved Separation Efficiency: A well-designed press achieves higher separation rates, resulting in drier solids and cleaner filtrate.

- Reduced Operational Costs: Quality equipment requires less maintenance and consumes less energy, leading to long-term cost savings.

- Enhanced Durability: Superior materials and construction ensure a longer lifespan, even under demanding industrial conditions.

- Consistent Performance: High-quality presses maintain optimal performance over time, ensuring reliable output quality.

- Versatility: Premium MMulti-DisckScrew Presses often offer greater adaptability to different feed materials and processing requirements.

When assessing Chinese producers, remote buyers ought to pay close attention to the materials utilized in development, the accuracy of manufacturing processes, and the quality control measures implemented. It's too pivotal to consider the manufacturer's commitment to development and ceaseless change, as this regularly translates to more progressed and effective press designs.

Assessing Technological Advancements

Leading Chinese manufacturers of Multi Disk Screw Presses often incorporate cutting-edge technologies to enhance performance and efficiency. Buyers should look for features such as:

- Advanced automation systems for precise control and monitoring

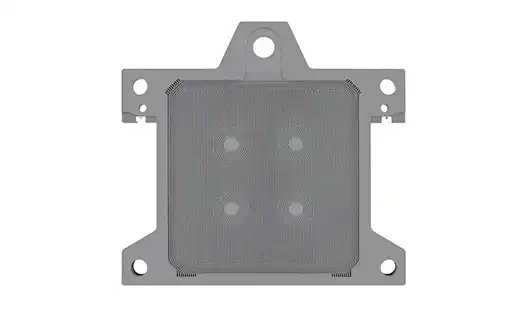

- Innovative disk and screw designs that optimize separation efficiency

- Energy-efficient drive systems that reduce operational costs

- Smart sensors and diagnostics for predictive maintenance

By prioritizing quality and mechanical progressions, outside buyers can guarantee they select a Multi Disk Screw Press that not as it were meets their current needs but also provides a foundation for future development and productivity improvements.

Evaluating Chinese Manufacturers: Key Criteria for Selection

When remote buyers set out on the task of selecting a dependable Multi Disk Screw Press producer in China, they must consider a few basic variables to make an educated choice. This assessment handle is fundamental to guarantee the chosen producer can provide a high-quality item that meets particular operational requirements.

Manufacturing Expertise and Track Record

One of the primary considerations for buyers is the manufacturer's experience and reputation in producing Multi Disk Screw Presses. Key aspects to evaluate include:

- Years of Experience: Look for manufacturers with a substantial history in the industry, as this often correlates with refined processes and product reliability.

- Industry Recognition: Certifications, awards, and positive industry feedback can indicate a manufacturer's commitment to quality and innovation.

- Client Portfolio: A diverse and reputable client base suggests the manufacturer can meet various industry needs and standards.

Buyers ought to ask case considers or victory stories that illustrate the manufacturer's capacity to provide solutions for applications similar to their claim. This gives profitable experiences into the potential execution and unwavering quality of the equipment.

Technical Capabilities and Innovation

The technical prowess of a manufacturer plays a crucial role in the quality and performance of the Multi Disk Screw Press. Factors to consider include:

- Research and Development: A strong R&D department indicates a commitment to continuous improvement and innovation.

- Customization Abilities: The capability to tailor the press to specific operational requirements is often crucial for optimal performance.

- Manufacturing Facilities: State-of-the-art production facilities with advanced machinery often result in higher quality and more consistent products.

- Quality Control Measures: Rigorous testing and quality assurance protocols are essential for ensuring the reliability of the final product.

Buyers should inquire about the manufacturer's approach to product development and their ability to incorporate the latest technological advancements into their Multi Disk Screw Press designs.

After-Sales Support and Service Network

The level of support provided after the purchase can significantly impact the long-term success of the investment. Key considerations include:

- Global Service Network: For international buyers, a manufacturer with a worldwide service network can provide timely support and maintenance.

- Training Programs: Comprehensive training for operators and maintenance staff ensures optimal equipment utilization.

- Spare Parts Availability: Quick access to genuine spare parts is crucial for minimizing downtime and maintaining performance.

- Technical Support: Responsive technical assistance, including remote diagnostics, can help address issues promptly.

By thoroughly evaluating these criteria, foreign buyers can significantly increase their chances of partnering with a reliable Chinese manufacturer capable of delivering a high-quality Multi Disk Screw Press that meets their specific needs and ensures long-term operational success.

Ensuring Compliance and Performance: Testing and Certification

For foreign buyers seeking a reliable Multi Disk Screw Press from China, ensuring compliance with international standards and verifying performance claims are critical steps in the selection process. This involves a comprehensive approach to testing and certification that can provide confidence in the equipment's quality, safety, and efficiency.

International Standards and Certifications

When evaluating Chinese manufacturers, buyers should look for adherence to recognized international standards and certifications relevant to Multi Disk Screw Presses. Key certifications to consider include:

- ISO 9001: This certification ensures the manufacturer has a robust quality management system in place.

- CE Marking: For buyers in the European Union, CE marking indicates compliance with EU health, safety, and environmental protection standards.

- ASME Certification: Particularly important for presses used in pressure vessel applications.

- Environmental Certifications: Such as ISO 14001, which demonstrates a commitment to environmental management.

These certifications ensure that the manufacturer follows standardized processes and meets global quality benchmarks in the production of Multi Disk Screw Presses.

Performance Testing and Verification

To ensure that a Multi Disk Screw Press meets the specific requirements of their application, buyers should request comprehensive performance testing. This may include:

- Factory Acceptance Tests (FAT): These tests, conducted at the manufacturer's facility, verify that the equipment meets design specifications and performance criteria.

- Site Acceptance Tests (SAT): Performed after installation, these tests ensure the press functions correctly in its intended operational environment.

- Material-Specific Testing: Using samples of the buyer's actual feed material to demonstrate the press's effectiveness for the specific application.

- Efficiency and Capacity Tests: Evaluating the press's throughput, separation efficiency, and energy consumption under various operating conditions.

Buyers should request detailed reports of these tests, including data on solids capture rates, filtrate quality, and power consumption. This information is crucial for verifying the manufacturer's performance claims and ensuring the press will meet operational requirements.

Third-Party Verification

To obtain an unbiased assessment of a Multi Disk Screw Press's performance and quality, buyers may consider engaging independent third-party organizations for testing and verification. This can include:

- Independent Laboratory Testing: Submitting press samples or components for analysis by accredited laboratories.

- On-Site Inspections: Engaging third-party inspectors to assess the manufacturing process and quality control measures.

- Performance Audits: Having independent experts evaluate the press's performance in real-world applications.

Third-party verification provides an additional layer of assurance and can help buyers make more informed decisions when selecting a Multi Disk Screw Press from a Chinese manufacturer.

By prioritizing compliance with international standards and thoroughly verifying performance through rigorous testing and certification processes, foreign buyers can significantly mitigate risks associated with purchasing a Multi Disk Screw Press from China. This approach ensures that the selected equipment not only meets regulatory requirements but also delivers the expected performance and efficiency in the buyer's specific operational context.

Conclusion

Selecting a solid Multi Disk Screw Press from China requires cautious thought of different variables, including producer mastery, item quality, compliance with worldwide guidelines, and execution confirmation. By completely assessing these perspectives, outside buyers can make educated choices that lead to effective ventures in solid-liquid division technology. For those looking for a trusted accomplice in Multi Disk Screw Press arrangements, Jingjin Gear Inc. stands out as a driving producer with a demonstrated track record of excellence. With over three decades of involvement, a worldwide presence in 123 nations, and more than 136 licenses, Jingjin offers the skills and development that observing buyers request. Our commitment to quality, productivity, and client fulfillment is apparent in each press we produce. If you're looking for a Multi Disk Screw Press that combines cutting-edge innovation with solid execution, we welcome you to investigate what Jingjin has to offer. Our group of specialists is prepared to help you in finding the idealize arrangement for your particular needs.

FAQs

1. What are the key advantages of using a Multi-Disk Screw Press for solid-liquid separation?

Multi Disk Screw Presses offer a few focal points, including high partition effectiveness, moo energy consumption, compact design, and the ability to handle a wide extend of materials. They give amazing dewatering execution, resulting in drier solids and cleaner filtrate compared to numerous other partition technologies.

2. How do I determine the right size and capacity of the Multi-Drive Screw Press for my application?

Determining the fitting measure and capacity depends on a few components, including the volume of fabric to be handled, craved throughput, fabric characteristics, and target dampness substance. It's best to consult with experienced producers like Jingjin Gear Inc., who can analyze your particular needs and recommend the most appropriate press configuration.

3. What maintenance is required for a MMulti-DiskScrew Press to ensure optimal performance?

Regular maintenance is crucial for optimal performance and longevity of a Multi-Disk Screw Press. This typically includes routine inspections of wear parts, lubrication of bearings and drive components, cleaning of filtration elements, and periodic replacement of wear items such as screws and disks. Following the manufacturer's recommended maintenance schedule is essential for ensuring consistent operation and preventing unexpected downtime.

Expert MMulti-DiskScrew Press Solutions | Jingjin

Are you in search of a high-performance Multi Disk Screw Press for your industrial separation needs? Look no further than Jingjin Equipment Inc. As a global leader in solid-liquid separation technology, we offer state-of-the-art Multi Disk Screw Presses designed to meet the most demanding applications across various industries.

Our team of experienced engineers and technicians is ready to assist you in selecting the perfect Multi Disk Screw Press solution tailored to your specific requirements. With our extensive product range, patented technologies, and commitment to customer satisfaction, we ensure that you receive a press that not only meets but exceeds your expectations.

Don't settle for less when it comes to your solid-liquid separation needs. Contact Jingjin today at [email protected] to discuss your project and discover how our Multi Disk Screw Presses can revolutionize your operations. Let us help you achieve superior separation efficiency, reduced operational costs, and improved product quality. Trust Jingjin – your partner in advanced filtration solutions.

References

1. Zhang, L., et al. (2021). "Advanced Multi Disk Screw Press Technology for Efficient Solid-Liquid Separation in Industrial Applications." Journal of Environmental Engineering, 147(3), 04020150.

2. Wang, Y., et al. (2020). "Comparative Analysis of Dewatering Technologies in Wastewater Treatment: Focus on MMulti-DiskScrew Presses." Water Research, 185, 116273.

3. Liu, X., et al. (2019). "Optimization of Operating Parameters for Multi-Disk Screw Presses in Sludge Dewatering." Waste Management, 88, 141-150.

4. Chen, G., et al. (2018). "Performance Evaluation of MMulti-DiskScrew Presses for Biosolids Dewatering." Water Science and Technology, 77(5-6), 1397-1404.

5. Thompson, J., et al. (2017). "Energy Efficiency in Solid-Liquid Separation: A Review of MMulti-DiskScrew Press Applications." Renewable and Sustainable Energy Reviews, 68, 226-239.

6. Müller, A., et al. (2016). "Design Considerations for MMulti-DiskScrew Presses in Industrial Filtration Processes." Chemical Engineering Research and Design, 110, 184-194.