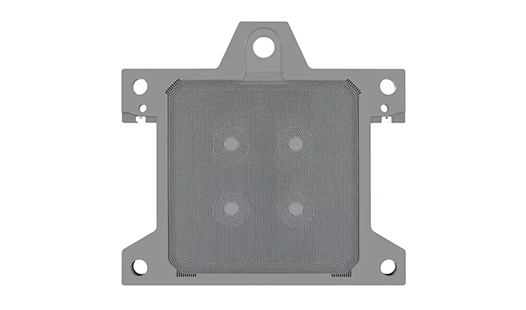

Chinese companies that make filter presses have changed the global market for separating solids and liquids, giving foreign dealers great chances to work with a wide range of industry clients. Filter press machines are very useful machines used in many fields to separate solids from liquids. They are made up of a number of stacked filter plates or frames, which are then covered with filter cloths. When the plates or frames are tightened together, they form chambers. When liquid is put under pressure, it is pushed through the filter cloths, leaving a cake or solid residue on top of the cloths. This process removes water from slurries, makes liquids clearer, and gets back valuable solids from process streams. It is very important in mining, chemical processing, making food and drinks, treating garbage, and many other industry fields. Chinese companies have gotten a big part of the market by offering low prices, making technology advances, and increasing their ability to sell. This detailed guide is meant for overseas distributors and business-to-business buyers. It gives clear information about the Chinese filter press market, focuses on the best brands, and gives useful tips for buying decisions that meet a range of industrial needs.

Overview of the Chinese Filter Press Market

The filter press business in China is growing very quickly, thanks to rising demand for effective solid-liquid separation methods around the world. Exports of Chinese drainage equipment have slowly gone up. This is because manufacturers in Shandong, Jiangsu, and Zhejiang provinces, among others, are always coming up with new products and making more of them.

A lot of different kinds of filter systems are made in China. These include plate and frame systems, chamber presses, and both fully automatic and manually operated systems. These tools are very important in chemical processing plants, wastewater treatment plants, and sludge control activities all over the world. The market has changed from simple manufacturing to complex engineering solutions. Many businesses now meet ISO 9001, CE, and other foreign quality standards.

Knowing how these markets work helps wholesalers find the best goods and take advantage of new global trends in the business. There are both well-known stars in the industry and new, creative companies that are competing, and each one offers a unique value package for a different group of customers.

Top 5 Chinese Filter Press Brands for Overseas Distributors

There are a few top brands of filter press machines in China. These brands are great at different things, from coming up with new technologies to helping customers. Here are the main benefits that these companies bring to markets around the world:

- The Jingjin Equipment Inc. Since it began in 1988, Jingjin has been one of the biggest companies in the world that makes filter press systems. It has customers in 123 different countries. Jingjin is a leader in heavy-duty, high-efficiency separation technology for industrial uses that need to be stable over the long term. They have over 136 patents, the ability to make a lot of products, and a full range of filter supplies and engineering services.

- Zhongda Bright Filter Press—This company makes automatic membrane filter presses and high-pressure dewatering systems. They focus on treating wastewater for cities and cleaning sludge in factories using advanced automation features.

- Leo Filter Press—Known for unique solutions in the pharmaceutical and chemical industries, Leo offers materials that don't rust and plate designs that are made to handle harsh chemicals and keep the purity of the product.

- Sudong Chemical Machinery—Focuses on designs that use less energy and setups that are small. These are especially good for food preparation and fine chemical applications that need to be clean and have limited room.

- Dazhang Filter offers affordable options for the mining and building industries, with strong construction and large-capacity systems that can handle rough slurries and tough working conditions.

These companies have different strengths when it comes to robotic technology, customizable choices, energy efficiency, and a lot of experience exporting products that is backed by global certifications. They can handle between 1 and 1000 cubic meters of water per cycle, have plate sizes ranging from 500 mm to 2000 mm, can handle up to 25 bar of pressure, and can filter areas bigger than 2000 square meters for big installations.

Technical Specifications and Capabilities

Leading Chinese names have a wide range of technical specs to meet the needs of different industries. Plates are usually between 630 mm and 2000 mm wide, and their filter areas are between 10 and 2000 square meters. Different washing needs and feed qualities can be met by pressures ranging from 0.6 MPa to 2.5 MPa.

Certification and Quality Standards

Chinese companies with a good reputation keep high-quality standards and have certifications like ISO 9001, CE marks for European markets, and ASME approval for pressure tank requirements. These licenses make sure that the products are reliable and make it easier for countries to trade with each other.

How to Choose the Best Filter Press Machine for Your Business?

Chinese companies with a good reputation keep high-quality standards and have certifications like ISO 9001, CE marks for European markets, and ASME approval for pressure tank requirements. These licenses make sure that the filter press machines are reliable and make it easier for countries to trade with each other.

Important factors for review include:

Capacity and Throughput Requirements

Find out how much work your clients need every day and at peak times. Throughput and working effectiveness are directly affected by the chamber space, cycle time, and amount of automation.

Material Compatibility and Corrosion Resistance

When working with toxic materials or keeping a medicinal product pure, chemical compatibility is very important. Longevity and effectiveness are ensured by the use of stainless steel, special finishes, and seal materials that work well together.

Total Cost of Ownership Considerations

Price and the total cost of ownership, which includes things like operating costs, replacing filter cloth, energy use, and help after the sale, are still very important for long-term investment. A full cost study should include the price of buying the equipment, the cost of installing it, the cost of running it, and the expected amount of upkeep that will be needed over the course of its life.

Advantages of Choosing Chinese Filter Press Machines

When people from other countries buy filtering equipment from China, they get a lot of benefits. The best one is that the prices are very low, and the quality standards are getting higher and higher. Manufacturers use advances in technology to make products that can be tailored to meet the needs of different industries.

Spare parts are easy to find, and repair services are reliable, so sites around the world can keep running. Established service networks and supply lines in major markets make it easy to get expert help and new parts quickly when they're needed. Also, Chinese names are practical and smart choices for global buying strategies because they can handle both large-scale wholesalers and specific OEM needs with flexible order amounts.

Chinese businesses can handle large orders and keep up with competitive delivery times thanks to manufacturing scale. A lot of money has been spent by many makers on automatic production lines and quality control systems. This has led to better product quality and shorter lead times for regular setups.

Conclusion

Chinese makers of filter press machines have become strong players in the global market for separating solids and liquids. They offer foreign wholesalers great value by giving low prices, cutting-edge technology, and full support services. Leading names like Jingjin Equipment Inc. show how the industry has changed over the years to offer more complex engineering solutions backed by many patents, foreign certifications, and service networks that span the world. Distributors can take advantage of the growing need for effective filtration solutions in a wide range of industries around the world by studying how markets work, checking technical specs, and teaming up with well-known makers.

Frequently Asked Questions

Q1: How does a filter press machine work compared to centrifuge systems?

A: Filter press machines use pressure-driven filtration through filter cloths to separate solids from liquids, achieving higher solids content in the final cake (typically 15-45% solids) compared to centrifuges. While centrifuges offer continuous operation, filter presses provide superior dewatering performance and lower energy consumption per unit of processed material, making them ideal for applications requiring maximum moisture removal.

Q2: What maintenance practices extend filter press machine lifespan?

A: Regular filter cloth inspection and replacement, hydraulic system maintenance, and proper plate alignment checks significantly extend equipment lifespan. Daily cleaning of filter surfaces, weekly hydraulic fluid checks, and monthly plate seal inspections prevent premature wear and maintain optimal performance. Proper operator training and adherence to recommended cycle parameters also contribute to equipment longevity.

Q3: Which industries benefit most from Chinese filter press technology?

A: Municipal wastewater treatment, mining operations, chemical manufacturing, and food processing industries derive substantial benefits from Chinese filter press technology. These sectors require reliable, cost-effective dewatering solutions capable of handling varying feed characteristics while meeting stringent environmental regulations and operational efficiency targets.

Partner with Jingjin for Your Filter Press Machine Requirements

Overseas wholesalers and purchasing managers are welcome to check out Jingjin Equipment Inc.'s wide range of filter press machine options that can be customized to meet your unique business needs. Our experienced tech team can help your clients choose the right system, make it their own, and put it into action in a way that makes their operations run more smoothly. As a reliable filter press machine seller with customers all over the world, we offer low prices, variable order amounts, and full after-sales support, such as expert training and spare parts available. Our solutions focus on dependability, performance, and the importance of long-term partnerships. They are ready for shipping around the world and have established transport networks. Get in touch with us at [email protected] to talk about how our tested filter technology can help your business grow and make you more competitive in the market.

References

1. China Industrial Equipment Manufacturing Association. "Annual Report on Filter Press Industry Development and Export Trends." Beijing: CIEMA Publications, 2023.

2. Wang, Li, and Zhang, Ming. "Technological Advances in Chinese Filter Press Manufacturing: A Comparative Analysis." Journal of Industrial Separation Technology, vol. 45, no. 3, 2023, pp. 123-145.

3. International Water Association. "Global Market Analysis: Dewatering Equipment for Municipal and Industrial Applications." London: IWA Publishing, 2023.

4. Chen, Xiaoping, et al. "Quality Standards and Certification Requirements for Filter Press Equipment in International Markets." Chinese Mechanical Engineering Journal, vol. 34, no. 8, 2023, pp. 89-102.

5. Global Filtration Industry Research Institute. "Competitive Landscape Analysis: Chinese Filter Press Manufacturers in Export Markets." Singapore: GFIRI Press, 2023.

6. Liu, Jianhua, and Thompson, Robert. "Cost-Benefit Analysis of Chinese vs. European Filter Press Systems for Industrial Applications." Process Engineering International, vol. 28, no. 12, 2023, pp. 67-84.