The Importance of Press Filter Equipment in Palm Oil Processing

A very important part of the palm oil production chain is the press filter equipment, which is used in both the extraction and purification processes. These high-tech tools are made to deal with the special problems that come up with palm oil mill wastewater, which has a lot of biological matter and a lot of different kinds of particles. Press filters use advanced filtering methods to separate solids from liquids. They can collect valuable oil leftovers that would otherwise be lost in the trash stream. This not only increases the general rate of palm oil output, but it also makes mill activities much less harmful to the environment.

Enhancing Oil Recovery and Quality

One of the best things about using modern press filter tools to handle palm oil is that it helps get more oil out of the oil. When old methods are used, they often leave large amounts of oil in the waste, which hurts the economy and the environment. Because modern press filters can handle high pressure and have exact filtration systems, they can get more oil out of the fruit that has been handled, which makes the mill work better overall. This faster recovery not only increases profits, but it also helps use resources in a more sustainable way, which is in line with efforts around the world to get the most out of current palm farms.

Environmental Compliance and Sustainability

As rules about the environment get stricter around the world, the palm oil business in Indonesia is under more and more pressure to reduce the damage it does to the environment. Press filter equipment is very important for dealing with these problems because it cleans palm oil mill wastewater well before it is dumped or used again. These filter systems help mills follow environmental rules and stay out of trouble by lowering the amounts of Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) in the wastewater. Also, being able to get water back from wastewater through efficient filtering helps with water saving, which is becoming more and more important in places where water is scarce.

Advancements in Press Filter Technology for Palm Oil Applications

In the past few years, there have been big improvements to the press filter tools used in Indonesia's palm oil business. These improvements are due to the need for better efficiency, dependability, and environmental performance. As technology has improved, filtering systems have become better at handling the unique challenges of making palm oil. They are now better at separating solids from liquids, recovering oil, and treating wastewater.

High-Pressure Filtration Systems

The creation of high-pressure filtration systems is one of the most important steps forward in press filter technology. These systems can work at pressures that are much higher than those used in regular filters. This makes it easier to separate solids from liquids. In the production of palm oil, this means better oil extraction rates and the ability to work with slurries that are thicker. High-pressure filtration also makes filter cakes that are dry and easier to handle and throw away, which speeds up the production process even more.

Automated Control Systems

Modern press filter equipment has more and more complex automatic control systems that make it easier to use and more consistent. Based on real-time data, these systems can constantly check and change filter factors like pressure, cycle time, and cake thickness to get the best results. For palm oil plants, this means more uniform product quality, less work for operators, and the ability to quickly adjust to changes in the feed's properties. Automation also makes things safer and saves money on labor, which makes it appealing to mill owners who want to bring their facilities up to date.

Selecting the Right Press Filter Equipment for Indonesia's Palm Oil Mills

Choosing the right press filter equipment is a big deal for Indonesian palm oil mill owners because it has a direct effect on how much oil they can make, how clean the oil is, and how well they follow environmental rules. During the decision process, many things need to be carefully thought through, such as the amount of waste that needs to be processed, its unique properties, and the company's long-term business goals.

Capacity and Scalability

One of the most important things to think about when choosing press filter equipment is whether it can handle the mill's current production level and also allow for growth in the future. The palm oil business in Indonesia is very active, and many mills want to grow to keep up with rising demand around the world. For this reason, it's important to pick filter systems that can both meet present needs and grow as needed. For example, flexible systems that are easy to grow could be chosen, or higher-capacity equipment that can handle more production without having to completely change the filter system could be chosen.

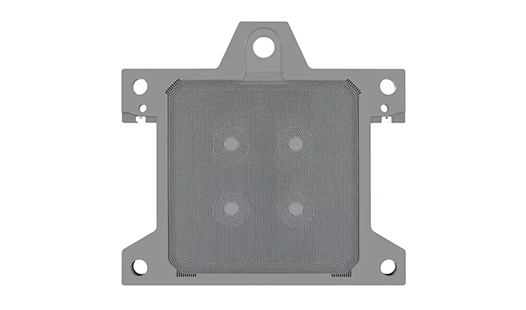

Material Compatibility and Durability

Because palm oil mill wastewater is so rough, you need to use press filter equipment made of materials that can handle being exposed to acidic and rough substances for a long time. Key parts like filter plates and frames are often made of materials that don't rust, like stainless steel or special metals. In addition, Indonesia has a warm environment with high temperatures and humidity, so equipment needs to be made to work consistently in these tough circumstances. Durability is very important because equipment that breaks down often or needs to be replaced too soon can have a big effect on working efficiency and costs.

Efficiency and Environmental Performance

As laws and concerns about the environment grow, how well the press filter equipment works and how little damage it does to the environment have become important factors in choosing such equipment. Mills should look for methods that can separate solids and liquids very well, so they can get the most oil out of the waste and make sure the waste meets or beats government standards. Better overall performance can be achieved by having features like high-pressure powers, effective cake washing systems, and the ability to handle different feed mixtures. It is also in line with environmental goals to use equipment that uses as little water and energy as possible. This can save costs over time.

Conclusion

For Indonesia's palm oil business to continue to be successful and last, it is important to choose and use high-tech press filter tools. It's more important than ever for the sector to invest in cutting-edge filter technology as it gets more pressure to improve efficiency, product quality, and environmental performance. Palm oil mills can improve their competitive edge in the global market and help make production more environmentally friendly by carefully examining their unique needs and picking equipment that offers the right mix of capacity, longevity, and efficiency. Working with experienced equipment makers is important for mill owners and other people involved in the industry who want to improve their filtration systems or learn more about the newest press filter technology. With its global service network and long history of solid-liquid separation solutions, Jingjin Equipment Inc. can offer custom filter solutions that are made to meet the specific needs of the Indonesian palm oil business. With the help of cutting-edge technology and all-around support, Jingjin helps palm oil makers run their businesses more efficiently, make their products better, and reach their sustainability goals.

FAQs

1. How does press filter equipment improve oil recovery in palm oil processing?

Press filter equipment improves oil recovery by applying high pressure to separate liquid from solid materials more effectively. This process extracts additional oil that would otherwise remain in the palm fruit pulp, increasing overall yield. Advanced press filters can recover up to 99% of residual oil, significantly boosting production efficiency and reducing waste.

2. What are the environmental benefits of using modern press filter equipment in palm oil mills?

Modern press filter equipment offers several environmental benefits, including reduced water consumption through efficient filtration and recycling processes, lower energy usage due to optimized operations, and improved effluent quality that meets stringent environmental standards. These benefits help minimize the ecological footprint of palm oil production and support sustainable industry practices.

3. How often should press filter equipment be maintained in a palm oil mill?

The maintenance frequency for press filter equipment in palm oil mills depends on factors such as operational hours, processing volume, and the specific model of the equipment. Generally, daily inspections, weekly cleanings, and monthly comprehensive maintenance checks are recommended. Major overhauls might be necessary annually or biannually. Regular maintenance ensures optimal performance, extends equipment lifespan, and prevents unexpected downtime.

High-Efficiency Press Filter Equipment for Palm Oil Processing | Jingjin

Are you looking to enhance your palm oil processing operations with cutting-edge filtration technology? Jingjin Equipment Inc. offers state-of-the-art press filter equipment specifically designed for the unique challenges of the Indonesian palm oil industry. Our solutions combine high efficiency, durability, and environmental performance to help you maximize oil recovery, meet regulatory standards, and improve overall operational sustainability. With over three decades of experience and a global presence in 123 countries, we understand the intricacies of palm oil production and can provide tailored filtration solutions to meet your specific needs. Don't let inefficient filtration hold back your mill's potential. Contact us today at [email protected] to learn how our advanced press filter equipment can transform your palm oil processing capabilities and drive your business forward.

References

1. Indonesian Palm Oil Association (GAPKI). "Annual Report on Palm Oil Industry Performance in Indonesia." 2022.

2. Subramaniam, V., et al. "Environmental Performance of the Milling Process of Malaysian Palm Oil Using the Life Cycle Assessment Approach." American Journal of Environmental Sciences, 2020.

3. Chin, M. J., et al. "Biogas from Palm Oil Mill Effluent (POME): Opportunities and Challenges from Malaysia's Perspective." Renewable and Sustainable Energy Reviews, 2019.

4. World Bank Group. "The World Bank in Indonesia: Overview of Palm Oil Sector." 2021.

5. Lam, M. K., and K. T. Lee. "Renewable and Sustainable Bioenergies Production from Palm Oil Mill Effluent (POME): Win-win Strategies Toward Better Environmental Protection." Biotechnology Advances, 2018.

6. Roundtable on Sustainable Palm Oil (RSPO). "Principles and Criteria for the Production of Sustainable Palm Oil." 2023 Revision.