More and more, European wholesalers are buying press filter machines from China because of the low prices, improved production skills, and ability to customize solutions that meet the needs of a wide range of industries. Strong supply lines have been set up by major Chinese makers like Jingjin Equipment. This lets European companies get high-quality filter equipment for treating garbage, making chemicals, mining, and medicinal uses. This smart approach to buying lets wholesalers take advantage of low-cost production while still meeting the high-quality standards needed by European markets.

Understanding Press Filter Machines and Their Market Demand

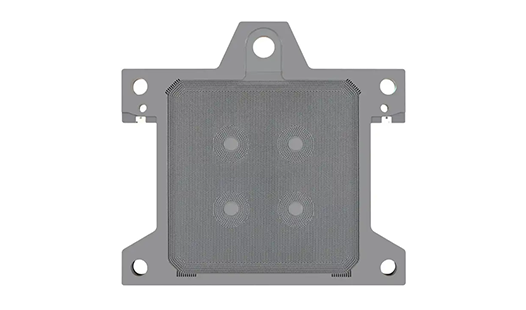

Machines called press filters are very good at separating solids from liquids and are used in many different types of industries. When put together correctly, these complex systems are made up of stacked filter plates that are separated by special filter cloths. This creates sealed rooms. Liquids move through the filter medium under controlled pressure, leaving behind concentrated solids on the cloth surfaces.

Technical Operation and Components

When slurry enters the chamber system under hydraulic or mechanical pressure, the filtering process starts. Solid particles are caught by filter cloths, which let clear liquid flow out of gathering holes. This system removes water from slurries, makes process liquids clearer, and gets valuable solids back from industrial waste streams. The resulting filter cake stays dry, which lowers the cost of removal and allows the material to be reused.

Industrial Applications Driving European Demand

There is a growing need for improved filtering systems in many important areas of the European market. For processing pigments, making resins, and making custom compounds, chemical companies need separation technology that they can rely on. Strong drainage systems are needed to handle waste and process concentrates in mining activities. To follow environmental rules, wastewater treatment plants put an emphasis on efficiently draining sludge.

More demand is caused by the pharmaceutical industry's needs for clean filters and API processing methods. These systems are used by businesses that prepare food to clear up drinks, make edible oils, and handle production waste streams.

Key Factors European Distributors Consider When Sourcing Press Filter Machines from China

When European wholesalers choose Chinese suppliers for filter equipment, they look at a number of factors. Fundamental needs include quality badges like ISO 9001 and CE marks, which show that they meet foreign standards. Manufacturing skills, such as production ability and customization choices, have a big impact on which suppliers are chosen.

Quality Assurance and Certification Requirements

Chinese companies that do well keep their quality control systems complete and in line with what people in Europe expect. Factory audits check how things are made, where the materials come from, and how the tests are done. There are material certificates, performance test results, and compliance statements for European import standards in the documentation files.

Leading companies like Jingjin Equipment show their dedication to quality by having a lot of patents and years of experience making things. These businesses spend money on research and development to make sure their goods meet changing customer needs and industry standards.

Machine Types and Configuration Options

European wholesalers look at the different ways that the press filter machine can be set up to make sure they meet the needs of each application. There are different types of machines for different types of work:

Hydraulic press filters can be used for high-volume tasks that need steady performance because they can precisely control the pressure and run on their own processes. Mechanical versions work reliably and need less upkeep, making them perfect for industrial processes that run all the time.

- Advanced control systems are built into automatic systems so they can run without a person being there. This cuts down on labor costs while keeping filter performance steady over longer production cycles.

- For smaller businesses or specific uses that need human help during the filtering process, manual setups are a cost-effective option.

- Designed with recessed plates, cake holders can hold more cakes while still taking up less room, making the best use of building space.

With these setup choices, wholesalers can offer customized solutions to meet the needs of a wide range of customers while still keeping prices low.

The Sourcing Process: How European Distributors Find and Verify Chinese Press Filter Suppliers

European wholesalers use organized methods to find and rate possible Chinese sellers. Online marketplaces like Alibaba, Made-in-China, and Global Sources offer initial source lists with basic information about companies and product listings. Trade shows let people talk to each other directly, so sellers can check the quality of products and get to know company officials on a personal level.

Supplier Verification and Due Diligence

Multiple steps of proof are used in a thorough seller review to lower the risks of buying. By visiting a factory, you can get a real sense of how well the production system works, how quality control is handled, and how management works. Checking references with current customers can give you an idea of how reliable a company is and how good their after-sales service is.

An evaluation of a supplier's financial health makes sure that they can handle large orders and stick to regular production plans. Third-party monitoring services check the manufacturing skills and compliance standards without being involved in the production process.

Negotiation and Contract Management

Negotiations that go well cover more than just unit price. Because customization is possible, providers can change common designs to fit unique needs or uses in the market. Original Equipment Manufacturer (OEM) agreements let dealers brand goods the way they want while still meeting quality standards.

Initial fees, progress payments during production, and final payouts upon delivery or launching are common ways to pay. What's covered by the warranty? Flaws in the equipment, performance promises, and the length of time for expert help. The installation and testing services make sure that the equipment is set up correctly and that operators are trained.

Practical Tips for Successful Press Filter Machine Procurement from China

Effective buying strategies keep risks to a minimum while getting the most out of Chinese sources. Clear design papers keep things clear during production and make sure that the equipment supplied meets operating needs. Communication that happens on a regular basis during production rounds lets problems be found and fixed quickly.

Quality Control and Inspection Procedures

Before the equipment is shipped, it is inspected to make sure the press filter machine meets quality standards and specs. Factory acceptance tests show that the machine works correctly in a controlled environment. Material approvals show that the parts are of good quality and meet European standards.

When it's not possible to visit the plant directly, third-party inspection services can be used to make sure of the quality. As part of these services, measurements are checked, materials are tested, and performance is confirmed according to standard procedures.

Logistics and Import Considerations

Shipping plans need to be carefully coordinated so that arrival times and shipping costs are kept to a minimum. Optimizing containers cuts down on freight costs and makes sure that equipment is safe during transport. Commercial bills, packing lists, and certificates of origin are some of the documents that need to be prepared in order to clear European customs.

Checking that equipment meets European safety and environmental norms is part of import compliance. The standards for CE marking make sure that the product follows the rules that apply. Having the right paperwork makes customs handling go more smoothly and cuts down on shipping delays.

Introducing Jingjin Equipment—Your Trusted Partner for Press Filter Machines

Since its founding in 1988, Jingjin Equipment Inc. has been one of the world's top makers of filter press systems and solid-liquid separation solutions. Jingjin serves customers in 123 countries by offering advanced filter technology for tough industrial uses. The company has more than 136 patents and a wide range of manufacturing capabilities.

Comprehensive Product Portfolio and Engineering Capabilities

Our selection of products includes hydraulic, mechanical, manual, and robotic press filter designs made to meet a wide range of business needs. Customization features let you change basic designs to fit the needs of a specific application or the limitations of how they work.

As part of engineering services, complicated industrial projects can get help with system design, process improvement, and integration. Our expert team works with customers to come up with solutions that solve unique, separate problems and make operations more efficient and cost-effective.

Global Service Network and After-Sales Support

Jingjin offers a full range of services, such as overseeing installations, teaching operators, and ongoing help for upkeep. Our global network makes sure that buyers all over the world can get quick expert help and extra parts. There are thorough operation instructions, upkeep plans, and repair tips in more than one language in documentation sets.

Conclusion

European wholesalers are able to get high-quality press filter machines from China by using clear quality standards and a structured way to evaluate suppliers. Leading Chinese companies like Jingjin Equipment have an edge over their competitors because they use cutting-edge technology, can customize their products, and offer full service support. Verifying suppliers, making sure specs are clear, and managing transportation well are all important parts of good buying strategies that make sure equipment is delivered and used correctly.

Frequently Asked Questions

Q1: How can I verify the quality of press filter machines sourced from China?

A: Quality verification involves multiple steps, including factory audits, material certification reviews, and pre-shipment inspections. Request documentation for ISO and CE certifications, conduct factory visits when possible, and engage third-party inspection services for independent quality assessment.

Q2: What is the average lead time for ordering a customized press filter machine?

A: Lead times typically range from 8 to 16 weeks depending on customization complexity and order size. Standard configurations may ship within 6-8 weeks, while highly customized systems require additional engineering and manufacturing time.

Q3: Are there energy-efficient press filter machine options suitable for European standards?

A: Yes, modern Chinese manufacturers offer energy-efficient designs incorporating variable frequency drives, optimized hydraulic systems, and automated controls that reduce power consumption while maintaining performance standards required by European regulations.

Partner with Jingjin for Your Press Filter Machine Requirements

Are you ready to get high-quality, reliable filtration tools from a maker of press filter machines that you can trust? Jingjin Equipment uses its many years of experience making things along with new technology to give you options that are exactly what you need. To make sure you succeed, our full-service method includes technical help, the ability to customize, and global after-sales support. You can talk to us about your needs and get specific quotes for your next project by emailing [email protected].

References

1. European Industrial Equipment Market Analysis Report, Industrial Equipment Research Institute, 2023

2. Global Filtration Technology Trends and Market Dynamics, Filtration Industry Association, 2023

3. China Manufacturing Export Statistics for Industrial Equipment, Chinese Manufacturing Association, 2023

4. European Import Regulations for Industrial Machinery, European Commission Trade Directorate, 2023

5. Solid-Liquid Separation Technology Advances in Industrial Applications, Process Engineering Journal, 2023

6. International Quality Standards for Filtration Equipment Manufacturing, International Standards Organization, 2023