What Is a Filter Press Plate and How Does It Work? A Comprehensive Guide to Slurry Filtration Plates

What Is a Filter Press Plate and How Does It Work? A Comprehensive Guide to Slurry Filtration Plates

The Anatomy of a Filter Press Plate: Design and Materials

- The Anatomy of a Filter Press Plate: Design and Materials

- How Filter Press Plates Work: The Filtration Process Explained?

- Optimizing Performance: Maintenance and Selection of Filter Press Plates

- Conclusion

- FAQs

- High-Performance Filter Press Plates for Efficient Slurry Filtration | Jingjin

- References

A Filter Press Plate is a vital component in mechanical filtration frameworks, designed to separate solids from fluids in various slurry applications. These specialized plates frame the spine of channel press innovation, empowering proficient dewatering and solid-liquid partition over different businesses. In this comprehensive direct, we'll investigate the complexities of channel press plates, their usefulness, and their imperative part in slurry filtration forms. Whether you're involved in wastewater treatment, mining operations, or chemical fabricating, understanding the mechanics and benefits of channel press plates is fundamental for optimizing your filtration frameworks and accomplishing predominant partition results.

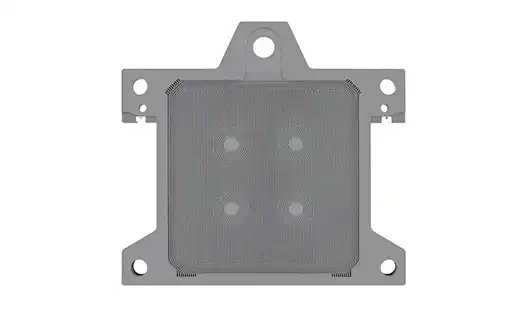

The Anatomy of a Filter Press Plate: Design and Materials

Filter press plates are designed with exactness to withstand the demanding conditions of mechanical filtration. These plates come in different plans and materials, each custom-made for particular applications and filtration requirements.

Plate Designs for Optimal Filtration

The design of a filter press plate plays a crucial role in its performance and efficiency. Common plate designs include:

- Recessed Chamber Plates: These plates feature a recessed area that forms the filtration chamber when pressed together. They are ideal for applications requiring high cake capacity.

- Membrane Plates: Equipped with a flexible diaphragm, these plates allow for additional squeezing of the filter cake, resulting in lower residual moisture content.

- Plate and Frame Design: This classic configuration uses alternating plates and frames to create filtration chambers, offering versatility and ease of maintenance.

Each design offers unique advantages, and the choice depends on factors such as the nature of the slurry, desired cake thickness, and filtration cycle time.

Materials That Matter

The durability and performance of filter press plates are heavily influenced by the materials used in their construction. Common materials include:

- Polypropylene: Lightweight, corrosion-resistant, and suitable for a wide range of chemical applications.

- Stainless Steel: Offers exceptional strength and resistance to high temperatures and aggressive chemicals.

- Cast Iron: Provides durability and cost-effectiveness for less corrosive applications.

- Nylon: Combines strength with chemical resistance, making it suitable for specialized filtration needs.

The selection of plate material is critical and depends on factors such as the chemical composition of the slurry, operating pressures, and temperature requirements.

How Filter Press Plates Work: The Filtration Process Explained?

Understanding the mechanics of how filter press plates function is key to appreciating their role in the filtration process. Let's break down the steps involved:

The Filtration Cycle

- Plate Assembly: The filter press plates are pressed together, creating sealed chambers between them.

- Slurry Feeding: The liquid-solid mixture (slurry) is pumped into these chambers under high pressure.

- Filtration: As pressure increases, liquid passes through the filter cloth attached to the plates, while solids are retained.

- Cake Formation: The retained solids build up, forming a "filter cake" within the chambers.

- Dewatering: Additional pressure may be applied to squeeze out remaining liquid from the cake.

- Cake Release: Once filtration is complete, the plates are separated, and the solid filter cake is discharged.

The Role of Surface Features

The surface of filter press plates is engineered with specific features to enhance the filtration process:

- Feed Eyes: These openings allow for the introduction of slurry into the filtration chambers.

- Drainage Channels: Grooves or channels on the plate surface facilitate the flow of filtered liquid.

- Sealing Surfaces: Precisely machined areas ensure a tight seal between plates, preventing leakage.

These features work in concert to maximize filtration efficiency and cake formation.

Optimizing Performance: Maintenance and Selection of Filter Press Plates

To ensure the longevity and efficiency of filter press plates, proper maintenance and selection are paramount. Here's what you need to know:

Maintenance Best Practices

Regular maintenance of filter press plates is essential for optimal performance:

- Cleaning: Regularly clean plates to prevent buildup and ensure proper sealing.

- Inspection: Check for wear, cracks, or deformation that could affect filtration quality.

- Filter Cloth Care: Properly maintain and replace filter cloths to prevent blinding and ensure consistent filtration.

- Lubrication: Keep moving parts well-lubricated to prevent unnecessary wear and tear.

Selecting the Right Plates for Your Application

Choosing the appropriate filter press plates for your specific needs involves considering several factors:

- Slurry Characteristics: Consider the chemical composition, particle size, and solids content of your slurry.

- Operating Conditions: Factor in pressure requirements, temperature ranges, and cycle times.

- Production Volume: Determine the required filtration capacity and cake thickness.

- Cake Release: Consider the ease of cake discharge based on your operational needs.

- Material Compatibility: Ensure the plate material is compatible with your process chemicals.

By carefully evaluating these factors—such as slurry characteristics, chemical compatibility, plate material, and operational requirements—you can select filter press plates that are best suited for your specific application. Choosing the right plates ensures efficient solid–liquid separation, minimizes wear and maintenance needs, and maximizes both performance and longevity, ultimately improving productivity and reducing operational costs.

Conclusion

Filter press plates are the unsung heroes of mechanical filtration, playing a pivotal part in isolating solids from fluids over a wide range of applications. From their perplexing plan highlights to the materials that make them strong and dependable, these components are basic for productive and successful slurry filtration. By understanding the mechanics of how channel press plates work and following best practices for upkeep and maintenance, businesses can optimize their filtration systems, reduce operational costs, and progress product quality. For those looking for high-performance filtration arrangements, Jingjin Hardware Inc. stands at the bleeding edge of channel press innovation. With over three decades of involvement and a worldwide presence in 123 nations, Jingjin offers cutting-edge channel press frameworks, plates, and cloths designed to meet the most demanding division challenges. Our commitment to development, sponsored by 136 licenses and large-scale fabricating capabilities, guarantees that we can give custom-fitted arrangements for any mechanical filtration need. Whether you're in mining, wastewater treatment, chemical fabricating, or any industry requiring solid-liquid partition, Jingjin has the skill and items to improve your operations. Do not let wasteful filtration hold your forms back. Contact Jingjin nowadays to find out how our progressed channel press plates and frameworks can change your filtration proficiency and drive your trade forward.

FAQs

1. How often should filter press plates be replaced?

The life expectancy of channel press plates shifts depending on utilization, support, and working conditions. By and large, well-maintained plates can a a long time. In any case, it's fundamental to frequently assess plates for signs of wear, such as cracks, distortion, or surface corrosion. If you note a diminish in filtration productivity or cake quality, it may be time to consider substitution. Counsel with a filtration master for a personalized appraisal of your system's needs.

2. Can filter press plates be used for all types of slurries?

Whereas channel press plates are flexible, not all plate sorts are appropriate for each slurry. The choice depends on variables like molecule measure, chemical composition, and the desired cake moisture. For illustration, film plates might be best for slurries requiring lower leftover dampness, whereas recessed chamber plates seem to be way better for high-solids substance slurries. It's pivotal to counsel with filtration masters to select the most suitable plate sort for your particular application.

3. How do I know if I need to upgrade my filter press plates?

Signs that it might be time to update your channel press plates include diminished filtration productivity, expanded cycle times, trouble in accomplishing desired cake moisture levels, or visit support issues. Furthermore, if your generation necessities have changed or you're managing with modern sorts of slurries, updating to more reasonable plates seems to essentially improve your filtration process. Conducting an exhaustive investigation of your current system's execution and consulting with filtration specialists can help decide if an overhaul is necessary.

High-Performance Filter Press Plates for Efficient Slurry Filtration | Jingjin

Ready to revolutionize your filtration process with industry-leading filter press plates? Jingjin Equipment Inc. offers a comprehensive range of high-quality filter press plates designed to meet the diverse needs of industries worldwide. Our advanced plates, manufactured with precision and durability in mind, are the key to achieving superior solid-liquid separation results.

Don't settle for subpar filtration performance. Contact our team of experts today to discuss your specific requirements and discover how Jingjin's filter press plates can optimize your operations. Reach out to us at [email protected] for personalized advice and solutions tailored to your industry needs. Let Jingjin be your partner in achieving filtration excellence!

References

1. Smith, J. D. (2021). "Advanced Filter Press Technology: Innovations in Plate Design." Journal of Industrial Filtration, 45(3), 178-195.

2. Johnson, A. R., & Thompson, L. K. (2020). "Material Selection for Filter Press Plates in Corrosive Environments." Chemical Engineering Progress, 116(8), 42-50.

3. Zhang, Y., et al. (2019). "Optimization of Filter Press Operation: A Comprehensive Review." Separation and Purification Technology, 215, 32-48.

4. Brown, M. E. (2022). "Filter Press Plate Maintenance: Best Practices for Longevity and Performance." Water Environment Federation Technical Exhibition and Conference (WEFTEC) Proceedings, 2022, 1523-1535.

5. Garcia, R. L., & Patel, S. V. (2020). "Comparative Analysis of Filter Press Plate Designs for High-Solids Slurries." Minerals Engineering, 153, 106372.

6. Wilson, D. H. (2021). "Advancements in Membrane Filter Press Plates for Enhanced Dewatering Efficiency." Filtration & Separation, 58(4), 18-23.

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog

Top Maintenance Tips for Prolonging the Life of Your Industrial Filter Press

Filter Press Solutions for India Pharmaceutical Plants from China

Why Vietnam Wastewater Plants Choose China Multi Disk Screw Press?

How Foreign Buyers Choose Reliable Multi Disk Screw Press in China?