China Filter Press Equipment Pricing for Industrial Buyers

Understanding Filter Press Equipment: Key Features and Industrial Applications

- Understanding Filter Press Equipment: Key Features and Industrial Applications

- Factors Influencing China Filter Press Equipment Pricing

- Comparison of Filter Press Equipment from China vs. Other Markets

- How to Choose the Right Filter Press Equipment for Your Industrial Needs

- Procurement and After-Sales Tips for Buying Filter Press Equipment from China

- Company Introduction and Our Filter Press Solutions

- Conclusion

- FAQ

- Ready to Transform Your Industrial Filtration Process with Jingjin

- References

Knowing how much filter press equipment from Chinese makers costs is important for making decisions about what to buy when it comes to business uses. The price of Chinese filter press equipment runs from $15,000 to $200,000, based on the size, amount of automation, and need for customization. Due to their low prices and high level of engineering, Chinese filter systems are a good choice for businesses that need to effectively separate solids from liquids. This includes mining, wastewater treatment, chemical processing, and pharmaceutical production.

Understanding Filter Press Equipment: Key Features and Industrial Applications

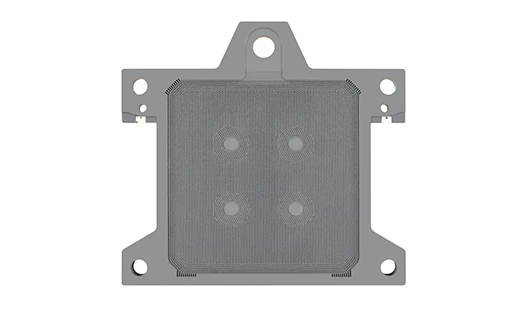

Filter press equipment is a high-tech mechanical way to separate solids from liquids in many different industry fields. The basic idea behind how it works is to force liquid through filter cloths under controlled pressure. This separates the liquid and solids efficiently while keeping the solids as a filter cake. This tried-and-true technology has changed a lot over the years, adding new materials and automation features that make it more reliable and improve performance.

Core Components and Working Mechanisms

When the press filter is pushed together, the filter plates and frames move back and forth, making sealed chambers. The means of separation is filter cloths placed between these plates. The clothes let liquid pass through while catching solid particles. The hydraulic closing system keeps the pressure the same on the whole plate stack, so the filtering works the same way all the way through the cycle. Programmable logic controllers are used in modern designs to handle the whole filtering process. This means that operators don't have to do as much wor,k and the process is more consistent.

Primary Industrial Applications

Mining companies use these devices to remove water from tailings, filter concentrate, and restore process water. Filter press equipment technology is used by chemical companies to separate pigments, work with resins, and clean up unique chemicals. Municipal wastewater treatment plants use these systems to remove water from sludge, which cuts down on the volume and costs of dumping by a large amount. The pharmaceutical and food preparation industries like the clean design features and accurate sorting options that keep product purity standards high.

Filter press systems are very useful for many things, including dewatering slurry in building projects, treating polluted soil in environmental cleanup efforts, and moving different concentrate materials around in metallurgical processes. Different uses need different plate materials, cloth choices, and pressure levels that are best for the separate problems that come up.

Factors Influencing China Filter Press Equipment Pricing

Figuring out what makes Chinese filter equipment so expensive helps industrial buyers make smart purchases and get the most out of their investments. Different prices are caused by several interconnected factors, each of which has an effect on both the original cost of cash and the long-term cost of operations.

Material Quality and Manufacturing Standards

Plate building materials have a big effect on how much equipment costs and how long it lasts. Polypropylene plates are resistant to chemicals and cost-effective for most uses. A stainless steel building, on the other hand, costs more but lasts longer in corrosive settings. Frames made of cast iron are strong enough for high-pressure uses and don't cost too much. The level of accuracy used in manufacturing affects the price. Tighter tolerances and better surface finishes cost more but provide better seals and longer service life.

Capacity and Automation Considerations

The price of equipment is directly related to the size of the filtration area. Equipment ranges from small 10-square-meter units good for test operations to huge 500-square-meter systems that can handle large-scale production needs. Systems that are operated by hand are cheaper at first, but they need a lot of work. Fully automated systems, on the other hand, have complex control systems, automatic plate shifting mechanisms, and built-in cleaning processes that make them more expensive by making operations more efficient.

Customization and Engineering Requirements

For common uses, standard setups are the most cost-effective option. On the other hand, customized designs that meet specific process needs are more expensive. For example, customized electricity systems for dangerous areas, special coatings for high or low pH levels, and built-in heating systems for temperature-sensitive uses are all examples of how customization can change price structures. Having engineering help with system integration, process improvement, and performance promises is useful, but it can change how much the whole project costs.

Comparison of Filter Press Equipment from China vs. Other Markets

Comparing Chinese filtration equipment to options from around the world needs more than just looking at the initial buy price. China's manufacturing has gotten better at quality control and using new technology to close performance gaps while keeping big cost benefits over European and American rivals.

Price Competitiveness Analysis

Chinese makers of filter press equipment usually offer prices that are 30–50% cheaper than European counterparts while still meeting the same performance standards. This lower cost comes from manufacturing processes that work well, supply lines that are competitive, and exchange rates that are good. When buyers compare choices from different supplier areas, they should look at the total cost of ownership, which should include shipping, installation, training, and long-term support.

Technology and Quality Comparisons

Leading Chinese companies have put a lot of money into research and development, which has led to the creation of new technologies like clever tracking systems, automatic cloth washing systems, and membrane squeeze systems. International standards are met by quality certifications like ISO 9001, CE marks, and approvals specific to the business. A lot of Chinese suppliers work together with European engineering firms on technical issues. This lets them save money while still using the best technology.

New versus Refurbished Equipment Considerations

For important uses, the higher initial investment is worth it because new equipment comes with a warranty, the newest technology, and reliable performance qualities. You can save a lot of money by buying a refurbished unit, but it might not have all of the latest technology features or a full guarantee. When choosing between new and used choices, the availability of real spare parts and expert help should be taken into account, especially for long-term operational planning.

How to Choose the Right Filter Press Equipment for Your Industrial Needs

To choose the right filter equipment, you need to carefully think about the process needs, practical limitations, and cost goals. When making a choice, technical specs should be weighed against practical factors like the amount of upkeep needed, the skill level of the operators, and the possibility of expanding the capacity in the future.

Application-Specific Requirements

For chemical processes, you need materials that don't rust and the ability to precisely control the temperature. In mining, structures need to be strong enough to resist rough materials and high pressure. For pharmaceutical uses, clean design features are needed, like building without cracks and proven ways to clean. Each industry has its own problems that need to be solved with different kinds of tools and materials.

Technical Specification Considerations

The filtration capacity should match the needs of production while also leaving room for growth in the future. The operating pressure must be able to handle the conditions of the process with enough safety gaps to spare. Even the cake width has an effect on the quality of the result and how well the cycle works. Cloth-changing systems affect how well the repair works and how much time is lost during operations. These technical factors have a direct effect on the choice of tools and the long-term happiness with performance results.

Investment and Performance Balance

When picking out equipment, you should try to get the best return on your investment in terms of both financial and operational benefits. Higher-capacity mechanical systems cost more to buy at first, but they get the job done consistently and more efficiently. Manual methods need more skilled workers and cost more to set up, but they are cheaper to buy. Total ownership costs include things like energy use, upkeep needs, and the cost of consumables. These costs should help you choose the right tools.

Procurement and After-Sales Tips for Buying Filter Press Equipment from China

To buy from Chinese sellers successfully, you need to know about their cultural business practices, logistics, and quality control processes. Clear documentation and good communication keep things from getting confusing and make sure that the equipment provided meets operating needs.

Logistics and Shipping Considerations

Standard equipment usually has lead times of 8 to 12 weeks, while special systems can take up to 16 to 20 weeks to plan, build, and test. When planning how to ship something, you should think about its size, how heavy it is, and which ports can handle it. Insuring your goods should cover damage in transportation and delivery delays. Different countries have different import taxes and processes for clearing customs, so projects need to be planned ahead of time to avoid delays.

Pricing Structure and Financial Planning

Chinese sellers usually offer good deals on large orders and supply agreements that last for a long time. Payment terms usually require deposits when the order is confirmed, and the rest of the money is due when certain production goals are met and the shipment is ready to go. Forward contracts may help big buying projects by protecting them from changes in the value of the currency. Financing choices like leasing equipment or using seller credit programs can help you better control your cash flow and make it easier to buy equipment.

Maintenance and Support Strategies

Preventive repair plans make sure that equipment lasts as long as possible and works reliably. Important wear parts like filter cloths, sealing elements, and hydraulic parts should be kept in stock as spare parts. Technical training for repair staff makes sure they know how to properly take care of tools and fix problems. Remote tracking systems make it possible to plan repairs and improve performance ahead of time, and they also cut down on unplanned downtime.

Company Introduction and Our Filter Press Solutions

Jingjin Equipment Inc. has been helping businesses in 123 countries since its start in 1988 and is now a world leader in solid-liquid separation technology. We are very good at making a wide range of things, like filter press equipment systems, special filter plates, high-performance filter cloths, and full filtration solutions for the toughest industrial uses.

Manufacturing Excellence and Innovation

Our state-of-the-art factories use cutting-edge production technologies and strict quality control systems to make sure that the quality of our products is always high. We constantly improve filter technology by investing in research and development. Our new designs are protected by over 136 patents. We can do jobs ranging from single units to full industrial setups because we can produce on a large scale. We also keep the quality of all of our products at a very high level.

Global Service Network and Support

The technical support infrastructure is spread out over several countries, so it can quickly respond to installation, testing, and ongoing maintenance needs with local knowledge. Our tech teams work closely with clients to create custom solutions that solve their specific process problems and meet their performance goals. Full instructions, training programs for operators, and performance promises make sure that the project is carried out successfully and that operators are happy with it for a long time.

Advanced filtration technology can be used by businesses of all kinds and types because there are a variety of financing choices that can fit different budgets and project timelines. We care about our customers' success in more ways than just delivering equipment. We also build long-term relationships with them that support operational excellence and projects for ongoing growth.

Conclusion

When it comes to value, Chinese filter press equipment stands out because it combines low prices, cutting-edge technology, and full support. Understanding the factors that affect pricing structures, comparing global options, and choosing equipment that meets their unique working needs are all benefits for industrial buyers. Paying attention to a supplier's qualifications, technical requirements, and long-term help is important for successful procurement. As China's industrial landscape changes, new solutions are being developed that meet foreign quality standards while still being cheaper. Careful consideration of the total costs of ownership, which includes the need for upkeep and support, helps make the best investment choices that will lead to long-term operational success.

FAQ

Q1: What are typical lead times for filter press equipment from Chinese manufacturers?

Standard filter press configurations typically require 8-12 weeks from order confirmation to shipment readiness. Customized systems with specialized materials or unique design features may extend lead times to 16-20 weeks, depending on engineering complexity and manufacturing requirements. Suppliers usually provide detailed production schedules during the quotation process, allowing buyers to plan project timelines accordingly.

Q2: How does energy efficiency impact the total cost of ownership?

Modern filter press systems incorporate energy-efficient hydraulic systems and optimized cycle programming that reduce operational costs by 20-30% compared to older designs. Variable frequency drives, efficient pumping systems, and intelligent control algorithms minimize energy consumption while maintaining performance standards. Energy savings typically offset higher initial equipment costs within 2-3 years of operation, making efficiency investments economically attractive.

Q3: What customization capabilities are available for specialized applications?

Chinese manufacturers offer extensive customization options, including explosion-proof electrical systems, specialized plate coatings for extreme chemical environments, integrated heating systems for temperature-sensitive processes, and sanitary designs meeting pharmaceutical standards. Custom automation levels, monitoring systems, and integration capabilities can be tailored to specific operational requirements and existing plant infrastructure.

Ready to Transform Your Industrial Filtration Process with Jingjin

Jingjin Equipment stands ready to deliver cutting-edge filter press equipment manufacturer solutions tailored to your specific industrial requirements. Our experienced engineering team provides comprehensive consultation services, detailed system specifications, and competitive pricing proposals that optimize your filtration investment. Contact our experts at [email protected] to discuss your project requirements and receive personalized quotations. Take advantage of our flexible financing programs and bulk order incentives designed to maximize value for your organization.

References

1. Industrial Filtration and Separation Technology Handbook, 4th Edition, Published by Process Engineering Publishers, 2023.

2. Global Filter Press Market Analysis and Forecast Report 2024-2029, International Industrial Equipment Research Institute.

3. Solid-Liquid Separation Equipment Performance Standards, American Society of Mechanical Engineers, ASME Standard B847-2023.

4. Chinese Manufacturing Quality Standards for Industrial Filtration Equipment, China National Standards Committee, GB/T 25102-2024.

5. Wastewater Treatment Equipment Procurement Guidelines for Municipal and Industrial Applications, Water Environment Federation, 2024.

6. Cost-Benefit Analysis of International Industrial Equipment Procurement, Journal of Industrial Engineering and Management, Volume 45, Issue 3, 2024.

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog

How Does a Filter Press Work in Wastewater Treatment? A Comprehensive Guide

Where Indian EPC Contractors Buy Multi Disk Screw Press in China?

Top Maintenance Tips for Prolonging the Life of Your Industrial Filter Press

Top China Screw Dewatering Machine Suppliers for Asia Markets

Common Problems with Filter Press Plates and How to Prevent Them

Energy Saving Multi Screw Sludge Press: How It Reduces Operational Costs