Why African Municipalities Choose China Dewatering Press Machines?

Understanding the Demand: Challenges in Municipal Dewatering Operations in Africa

- Understanding the Demand: Challenges in Municipal Dewatering Operations in Africa

- Advantages of China Dewatering Press Machines for African Municipalities

- Types of Dewatering Press Machines Offered by Chinese Manufacturers

- How to Choose the Optimal Dewatering Press Machine for Municipal Use?

- Maintenance Tips and Common Issues of Dewatering Press Machines

- Environmental Impact and Industry Trends Influencing Procurement Decisions

- Company Profile and Comprehensive Dewatering Solutions

- Conclusion

- FAQ

- Partner with Jingjin for Advanced Municipal Dewatering Solutions

- References

African cities and towns are turning more and more to dewatering press machines made in China to help them deal with their growing wastewater treatment problems. The advanced filter technology, low prices, and strong engineering make these systems very appealing for city governments that are trying to stick to tight budgets and meet strict performance standards. Chinese companies that make dewatering press machines offer complete solutions that separate solids and liquids more effectively while still being reliable in difficult African environments. This makes them the best choice for long-term control of city wastewater.

Understanding the Demand: Challenges in Municipal Dewatering Operations in Africa

As growth speeds up across Africa, cities and towns are facing problems managing garbage that has never been seen before. Rapid population growth in places like Lagos, Nairobi, and Accra has put too much stress on the infrastructure that is already there. This means that effective sludge draining solutions are needed right away. It's hard for many city treatment plants to meet current performance standards because they use old equipment. This leads to higher costs and problems with following environmental rules.

Infrastructure Limitations and Budget Constraints

The sewer systems in many African towns are very old, which makes them hard to use. Engineers in cities and towns often have to work with systems that were put in place decades ago and aren't as reliable or efficient as they need to be for today's needs. Budget constraints make choices about upgrades even harder because cities and towns have to balance initial costs with ongoing operating costs. Traditional European or American equipment often costs more than planned, so companies must find cheaper options to stay in business.

Environmental Regulations and Compliance Requirements

Environmental laws are getting stricter in many African countries, which is pushing cities and towns to use more advanced drainage technologies. South Africa, Kenya, and Morocco, among others, have stricter discharge guidelines that need improved solid-liquid separation capabilities. Managers of municipal garbage must make sure that their dewatering systems can regularly meet moisture content goals while also following the rules set by local environmental authorities.

Operational Efficiency and Maintenance Considerations

When a municipality runs its business, it needs tech that works well and has little downtime. Many African cities and towns don't have a lot of expert staff, so choosing equipment that is easy to maintain and use is very important. The need to run continuously 24 hours a day and the harsh conditions of the environment mean that the engineering has to be strong and the performance has to be reliable so that it can handle the tough operating settings.

Advantages of China Dewatering Press Machines for African Municipalities

Chinese companies have made dewatering press machines that are especially designed to deal with the problems that African cities and towns have. These systems use cutting-edge filter technology and are designed in a way that puts dependability, efficiency, and low cost first. The engineering method focuses on getting the best performance while keeping things simple to use and durable over time.

Superior Cost-Performance Balance

Chinese dewatering equipment is very cheap because the production process is optimized and the supply chain is simplified. Municipal procurement managers can get advanced filtration technology from new sources for a lot less money than from old ones. This lets towns that are watching their budgets use modern dewatering options. This lower cost makes it possible to make big changes to the system that wouldn't be possible otherwise. This helps all city treatment centers work more efficiently.

Advanced Technology Integration

Modern Chinese dewatering press machines have advanced automatic systems and sensor technology that make them more reliable. Rotating screws and fixed disks work together in multi-disk screw press designs to crush feed material and remove liquid content efficiently. These systems are very good at separating things because, as the material moves through the compression chamber, the pressure and shear forces increase. This makes a high-quality, low-moisture product that meets the needs of city disposal.

Robust Engineering for Challenging Environments

Chinese companies make sure that their dewatering tools can work in the tough conditions that are typical in African cities. Materials that don't rust and stronger buildings make sure that it works well in places with high temperatures and humidity. The spiral extruded sludge thickener design has many benefits, such as keeping the size small and using little water for cleaning. This makes it perfect for cities that are limited on space and want to save water.

Types of Dewatering Press Machines Offered by Chinese Manufacturers

Chinese companies offer a wide range of dewatering options that can be customized to meet the needs of different cities and work limits. The range of equipment includes small screw press systems and big belt press setups. Each is designed to handle different types of sludge and large amounts of processing.

Screw Press Systems for Municipal Applications

Screw dewatering press machines work great for processing sewage sludge in places where space is limited, and operation is easy. These systems are built with combined assembly construction, which makes installation easier and saves important floor space compared to other options. The spiral extruded design can handle sludge concentrations between 0.2% and 2%, and can reach end concentrations above 5% by compressing the sludge efficiently.

Moving ring technology, which is used in more modern screw press designs, cleans the filter slits automatically. Moving and stationary rings meet while the spiral shaft drives circular motion. This makes the machine clean itself, which uses less water. This new method cuts the amount of clean water needed to less than 1% of what is needed for regular thickening equipment, which helps cities meet their water-saving goals.

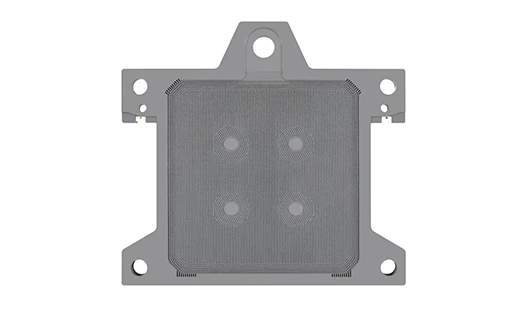

Multi-Disk Screw Press Technology

Multi-disk screw press systems are the newest development in technology for separating solids and liquids in urban settings. These machines use both screw compression and multiple disk filtering to separate things very well and process a lot of data quickly. The screw and disk design can be changed, which gives exact control over the compression processes and ensures the best separation performance for the different types of sludge that are found in city operations.

Advanced automatic and control systems built into multi-disk designs make operation smooth and allow tracking in real time. Automatic features that adapt to changing feed conditions and processing needs help municipal workers get consistent product quality and the most out of their operations.

Automated vs Manual Operation Options

Chinese makers make both automatic and human dewatering systems so that they can work with a range of city budgets and levels of operating complexity. Comprehensive sensor networks in automated systems allow them to work 24 hours a day, 7 days a week, without any human intervention. If something goes wrong, the system will automatically sound a warning and shut down. These methods work well for bigger city operations that need to handle things all the time to meet treatment capacity needs.

Manual operation models are a cheap way for smaller cities or sites that don't need a lot of technology to get things done. These systems offer the same core dewatering performance while having easier-to-use control panels and lower original investment costs. This means that cities and towns with limited funds can now use modern filtration technology.

How to Choose the Optimal Dewatering Press Machine for Municipal Use?

When choosing the right dewatering tools, you need to carefully consider a number of factors that affect both the short-term performance and the long-term success of the job. Engineers working for cities have to make sure that the tools they choose can meet regulatory compliance standards and operating reliability goals while also staying within the city's budget.

Capacity and Performance Evaluation

The main thing that is used to choose local dewatering press machines is their processing ability. Engineers have to look at the amount of sludge that is made every day, and the peak processing needs, to make sure that the systems they choose can meet practical needs without creating jams. Screw press systems work best for small to medium-sized businesses, while multi-disk designs can handle the higher throughput needs of bigger government facilities.

How well moisture reduction works has a direct effect on dumping prices and following the rules. Specifications for equipment should make it clear what level of dry solids is possible for different kinds of sludge that are used in city operations. Systems that can get a higher dry solids content lower the amount of waste that needs to be thrown away and the costs of transporting it. This saves money in the long run, which covers the cost of the initial equipment purchase.

Supplier Evaluation and Quality Assurance

A thorough evaluation of suppliers guarantees that tools will work and assistance will be available in the future. The teams that buy things for cities should look at the licenses, quality control systems, and foreign compliance standards of the manufacturers. Chinese companies like Jingjin Equipment Inc., which has been in business for over 35 years and has operations in 123 countries, are reliable and can provide help anywhere in the world, which is important for city operations.

The level of after-sales service and the length of the guarantee have a big effect on the total cost of ownership. Comprehensive service agreements that cover things like installation help, operator training, and preventative repair programs are very helpful for local teams' operations. Technical help and managing the collection of spare parts make sure that equipment downtime is kept to a minimum when it needs to be serviced or fixed.

Maintenance Tips and Common Issues of Dewatering Press Machines

Maintenance plans that work well keep technology running for longer, keep it working well, and increase its efficiency. Municipal maintenance teams can avoid common problems by following preventative maintenance plans that are made to fit the tools they are working on and the circumstances they are working in.

Preventive Maintenance Best Practices

Routine check plans are the basis of good care for dewatering equipment. Key parts like drive systems, filter elements, and hydraulic parts should be inspected visually every day for signs of wear or strange behavior. Lubrication plans that are done once a week make sure that mechanical parts work properly and don't wear out too quickly, which could cause expensive fixes or longer downtime.

When compared to older methods, modern screw presses require less upkeep because they clean themselves automatically. But cleaning the filter holes and compression chambers by hand regularly keeps them working at their best and stops materials from building up that could lower the efficiency of separation. To get the most out of maintenance intervals, cleaning methods should take into account the features of the sludge in the area and how it is used.

Common Operational Challenges

In city dewatering uses, clogging is the most common problem that comes up during operation. In most cases, this is caused by improperly prepared feed or working conditions that are higher than the equipment's design limits. Using the right screening and feed conditioning methods can stop most clogging problems and keep processes running smoothly.

Particular care needs to be taken with hydraulic system repair in Africa, where extreme temperatures and dust can affect the dependability of parts. Filters should be changed, and hydraulic fluid should be analyzed regularly to avoid pollution problems that could cause the system to fail. Temperature tracking systems let workers know when conditions might mean that they need to make changes to the system or do some maintenance.

Scheduling the replacement of wear parts based on operating hours and processing amounts keeps performance stable and stops failures that come up out of the blue. Key wear items, like filter plates, seals, and drive parts, should be kept in local stock so that planned repair activities don't cause too much downtime.

Environmental Impact and Industry Trends Influencing Procurement Decisions

Along with standard cost and performance factors, sustainability is becoming a bigger part of municipal buying strategies. Modern dewatering press machines help the environment a lot by making processes more efficient, using less energy, and recovering resources more effectively, which is in line with the principles of the cycle economy.

Sustainability and Resource Recovery

With the help of new dewatering technology, cities can get more dry solids out of processing sludge, which means less waste to be thrown away and less pollution from traffic. Electricity-saving features in Chinese-made systems keep power use low while still providing excellent splitting performance. The small design footprint means that local treatment plants need less room and don't have to pay as much for infrastructure.

Resource recovery potential is something that forward-thinking cities and towns are starting to think about. Modern filtration systems can work with anaerobic digestion and biogas recovery systems. This lets cities and towns turn garbage streams into clean energy. This combination helps reach sustainability goals and adds new income streams that make the project more profitable.

Technology Integration and Smart Systems

Municipal drainage operations are changing because of trends in the industry toward smart technology and IoT integration. New Chinese equipment uses high-tech sensors and data management systems that let you keep an eye on things from afar and plan repairs ahead of time. These features help management teams in cities by giving them real-time information on performance and making the best use of repair schedules.

Digital integration lets cities and towns set up full asset management systems that keep track of how well equipment is working, when it was last serviced, and other data that measure operating efficiency. This data-driven method helps people make smart choices about how to improve equipment and when to replace it. It also makes sure that regulations are followed by keeping detailed records of how well treatments are working.

Company Profile and Comprehensive Dewatering Solutions

Jingjin Equipment Inc. has been a specialist in solid-liquid separation technology for more than 35 years and brings that knowledge to local markets in Africa. The company has been around since 1988 and has become a world leader in filter press systems and filtering solutions. They have customers in 123 countries and offer a wide range of products and expert support.

Engineering Excellence and Innovation

Jingjin's large patent collection, which includes more than 136 new ideas, shows that the company is always working to improve filtering technology. The engineering team at the business creates unique solutions for difficult local uses, making sure that the systems work well in a variety of settings. Large-scale manufacturing lets you keep up a regular level of quality while keeping prices low enough to meet the needs of local budgets.

Along with the main dewatering equipment, the complete product environment includes filter plates, filter cloth, and consumable parts that make sure the equipment will work reliably for a long time. This unified method makes the purchasing process easier for city clients and makes sure that all system parts work well together and are compatible.

Global Service Network and Technical Support

Jingjin's global service network offers full support throughout the entire lifetime of an item of equipment, from the original consultation and system design to installation, commissioning, and continued upkeep. Technical training programs make sure that city operations teams can get the most out of their tools while still meeting safety and dependability standards.

Quality certifications and following international standards show that Jingjin is dedicated to providing dependable answers for important city-building uses. Initiatives for continuous growth and incorporating customer feedback help with product development that adapts to changing municipal needs and practical problems.

Conclusion

African cities and towns choose Chinese dewatering press machines because they offer the best mix of advanced technology, low cost, and reliable operation needed to handle the difficulties of modern wastewater treatment. Well-known companies like Jingjin Equipment offer complete options that meet the needs of different cities while also supporting environmental goals and following the rules. Chinese dewatering technology has been used and proven to work well in a wide range of situations and uses. It is a smart investment in the long-term growth of local infrastructure that pays off in both short-term and long-term ways.

FAQ

Q1: What capacity ranges are available for municipal dewatering applications?

Chinese manufacturers offer dewatering press machines ranging from small-scale units processing 1-5 cubic meters per hour to large municipal systems handling over 50 cubic meters hourly. Screw press systems typically accommodate 2-20 cubic meters per hour, while multi-disk designs can handle higher capacities up to 100+ cubic meters per hour for major municipal operations.

Q2: How do Chinese dewatering machines compare to European alternatives?

Chinese dewatering equipment provides comparable technical performance to European systems while offering significant cost advantages. Quality improvements over recent years have eliminated previous performance gaps, while competitive pricing makes advanced technology accessible to budget-conscious municipalities. After-sales support networks have expanded globally, ensuring reliable technical assistance.

Q3: What warranty and service support is available?

Reputable Chinese manufacturers provide comprehensive warranty coverage, typically ranging from 12 to 24 months on major components. Service agreements include installation support, operator training, preventive maintenance programs, and spare parts availability. Global service networks ensure responsive technical support for African municipal operations.

Q4: Can these systems handle variable sludge characteristics?

Modern Chinese dewatering systems feature adjustable operating parameters that accommodate varying sludge characteristics common in municipal operations. Multi-disk screw press designs particularly excel at handling diverse feed materials with different moisture levels and consistencies, providing consistent performance across changing operational conditions.

Partner with Jingjin for Advanced Municipal Dewatering Solutions

Municipal leaders seeking reliable dewatering press machine suppliers for their wastewater treatment facilities can benefit from Jingjin's comprehensive expertise and proven track record across African markets. Our engineering team provides customized consultation services to evaluate your specific requirements and recommend optimal equipment configurations that balance performance, cost, and operational considerations. Contact our technical specialists at [email protected] to discuss your municipal dewatering challenges and explore how our advanced filtration solutions can enhance your treatment facility's efficiency and environmental compliance.

References

1. African Development Bank. "Water and Sanitation Infrastructure Development in Sub-Saharan Africa: Municipal Treatment Facility Modernization Report." Infrastructure Development Journal, 2023.

2. International Water Association. "Sludge Dewatering Technologies for Developing Nations: Performance Analysis and Cost-Benefit Assessment." Water Technology Review, 2024.

3. United Nations Human Settlements Programme. "Urban Wastewater Management in African Cities: Technology Transfer and Equipment Procurement Guidelines." UN-Habitat Technical Series, 2023.

4. World Bank Group. "Municipal Infrastructure Investment in Africa: Wastewater Treatment Technology Selection and Procurement Best Practices." World Bank Publications, 2024.

5. African Water and Sanitation Association. "Dewatering Equipment Performance Standards for Municipal Applications: Comparative Analysis of Global Suppliers." AWSA Technical Bulletin, 2023.

6. International Finance Corporation. "Sustainable Infrastructure Development in Sub-Saharan Africa: Municipal Water and Wastewater Treatment Technology Assessment." IFC Industry Report, 2024.

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog

High Durability Filter Press Cloth for Chemical Processing: Benefits and Uses

Top China Screw Dewatering Machine Suppliers for Asia Markets

Where Indian EPC Contractors Buy Multi Disk Screw Press in China?