Indian EPC companies that want multi-disk screw presses are increasingly buying them from Chinese makers. These contractors buy their tools in China's strong industrial belt, which goes through the provinces of Shandong, Jiangsu, and Zhejiang. There, specialized makers like Jingjin Equipment have set up top-notch factories. These areas provide complete solid-liquid separation options based on cutting-edge technology, reasonable costs, and a lot of experience working with global EPC markets.

Understanding Multi-Disk Screw Press Technology and Industrial Applications

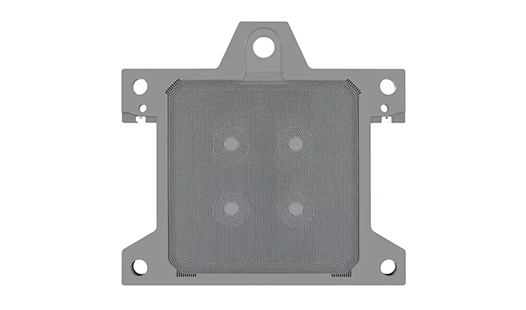

The multi-disk screw press is a groundbreaking new solid-liquid separation tool. It uses several spinning disks and precisely designed screw mechanisms to get amazing results in dehydration. Using constant compression, this advanced machine pushes materials through areas that get smaller and smaller between plates while the screw mechanism applies controlled pressure.

Core Technology and Operating Principles

The spinning screws and fixed disks work together to crush and squeeze feed materials. As materials move through the press, they experience higher levels of pressure and shear forces. This leads to better moisture removal and a higher-quality end product. The screw and disk design that can be changed makes it possible to fine-tune the compression process exactly how you need to for a wide range of uses, from treating wastewater in the city to managing industrial sludge.

Key Advantages for EPC Projects

Today’s spiral extruded sludge dehydrators have amazing benefits that make them very appealing for use in large-scale EPC projects. These benefits directly help workers with common business problems:

Thanks to its combined assembly design, the equipment is very space-saving, easy to install, and requires very little room in the building. This small arrangement is very helpful for projects with little room to work with or displays in cities where every square meter matters.

-

Water Conservation Technology: New moving ring systems make overlapped patterns of motion that clean filter slits on their own. This uses less than one percent of the water that standard thickening equipment uses.

-

The ability to do things automatically: Comprehensive sensor networks allow operation around the clock without needing to be there, with automatic alarm and stop features that activate during failure events.

-

Wide Concentration Range Processing: The multi-disk screw press processes sludge with concentrations from 0.2% to 2% and always gets product concentrations higher than 5%.

EPC companies that manage complicated industrial setups get these tech perks as practical ones that can be measured, like lower costs for upkeep, better compliance with environmental rules, and higher profits for projects.

Why Chinese Manufacturers Dominate the Indian EPC Market?

Chinese providers have become the top choice for Indian EPC companies by offering a range of benefits that meet the needs of the market. Indian builders and Chinese producers have built smart partnerships based on a shared understanding of project needs and delivery times.

Competitive Pricing Without Quality Compromise

Chinese builders keep up with foreign quality standards and offer prices that are very appealing to Indian EPC vendors. This price benefit comes from the ability to make goods in large amounts, cutting-edge manufacturing methods, and better control of the supply chain. Jingjin Equipment is a company that was started in 1988. Over the years, companies like this one have improved their ways of making things in order to get the best cost-efficiency ratios.

Comprehensive Product Ecosystem and Customization

Indian workers can get just the right tools for their projects because of the wide range of available options. Chinese makers offer a lot of different ways to customize equipment so that it can handle the unique types of trash, volume needs, and common weather conditions of Indian industrial operations. This ability to adapt is very important for EPC projects because they have to be able to meet different client needs in a range of industries.

Global Service Network and Technical Support

Established Chinese makers offer a lot of support after customers buy their products. This includes guaranteed coverage, the ability to get extra parts, and programs that help people with technical issues. These support networks reach Indian markets through local reps and service centers, which make sure that business stays up and running during all stages of the equipment's life.

Comprehensive Supplier Selection Strategies for EPC Contractors

A buyer needs to consider many things that affect both short-term and long-term business success when choosing the right providers. Indian EPC companies have to make tough choices that find a mix between expert skills, service promises, and business terms.

Technical Specification Evaluation

Procurement teams should focus on providers who have a lot of experience with solid-liquid separation methods and can show that they've done similar jobs well in the past. Technical review has to include efficiency rates, capacity ranges, energy use patterns, and upkeep needs. When suppliers give you a lot of specialized information, like process flow maps and performance promises, they usually make your project safer.

Quality Assurance and Certification Standards

ISO 9001, CE marks, and other approvals specific to the industry are examples of foreign licenses that top Chinese makers keep to make sure they follow global rules. Companies that have a lot of patents, like Jingjin Equipment with more than 136 patents, show that they are committed to continuing to innovate and lead in technology. These qualifications give EPC workers who are in charge of projects with strict quality standards peace of mind.

Commercial Terms and Delivery Capabilities

If you want to have a good relationship with your suppliers, you need to know how much things cost, when you have to pay, and when things will be delivered. Chinese makers are often able to make deals that take into account the project finance needs and delivery plans that are common in big EPC operations. Suppliers with well-known transportation networks can make sure that goods are delivered on time while also handling the paperwork and import processes.

Success Stories: Indian EPC Contractors and Chinese Equipment Integration

When Chinese makers make multi-disk screw press tools, they can be used in real life and show that they are helpful. These examples show that choosing the right suppliers and properly integrating tools can help projects succeed in a wide range of industries.

Municipal Wastewater Treatment Projects

Indian EPC companies working on local wastewater treatment facilities have been able to significantly improve their operations by using Chinese-made drainage equipment. In places like Pune and Chennai, projects showed that sludge moisture levels dropped from 85% to less than 60%. This helped the projects follow environmental rules and lowered the costs of getting rid of the sludge. The automatic operation features were especially useful because they let city workers keep the performance level steady with very little expert help.

Industrial Application Successes

Strongly built and corrosion-resistant materials from Chinese sources have helped chemical processing plants and mines. One Hyderabad project in pharmaceutical manufacturing cut the costs of managing waste by 40% and improved product quality by controlling wetness exactly. It was important that the equipment could handle different feed amounts because it was used to manage a variety of trash from different production processes.

Operational Lessons and Best Practices

Successful installations show how important it is to plan everything out ahead of time, including site preparation, power hookups, and training programs for operators. Chinese expert support during the launching phase helped projects meet their performance goals more quickly and kept them running reliably during the first working time.

Jingjin Equipment: Your Trusted Multi-Disk Screw Press Manufacturer

Jingjin Equipment is the world leader in solid-liquid separation technology. They provide complete filter solutions for tough industrial uses to customers in 123 countries. Our company has built up a wide range of tools and services since 1988 to meet the needs of EPC workers who work on complicated wastewater treatment and industrial processing projects.

We can make all kinds of sorting tools, from normal multi-disk screw presses to highly personalized systems built for specific industrial uses. Jingjin would be a great partner for Indian EPC companies looking for dependable, high-performance equipment suppliers because of its large-scale production capacity, extensive research and development resources, and global service network.

Our many patents and ongoing technology development projects are examples of how the company is dedicated to innovation. Our engineering teams work with EPC companies to make sure they understand the needs of each project. They then come up with custom solutions that improve performance while lowering the costs of running the project. This team-based method makes sure that the merging of tools is in line with the goals of the general project and the hopes of the client.

Conclusion

Indian EPC companies have found safe places to get multi-disk screw press tools by working with well-known Chinese makers. China is a great place to get solid-liquid separation tools because of its reasonable prices, cutting-edge technology, and great customer service. Procurement success relies on carefully evaluating suppliers, making sure technical specs are clear, and developing partnerships that go beyond the delivery of tools to include long-term operating support and service promises.

Frequently Asked Questions

Q1: What are typical lead times for multi-disk screw press orders from Chinese manufacturers?

A: Standard lead times range from 30 to 60 days, depending on equipment size and customization requirements. Complex installations requiring extensive modifications may require additional time for engineering and testing phases.

Q2: How do Chinese multi-disk screw presses compare to traditional dewatering equipment in terms of energy consumption?

A: Modern multi-disk screw presses typically consume 30-40% less energy than conventional belt filter presses while achieving superior moisture removal. The automated cleaning systems and optimized screw designs contribute to enhanced energy efficiency.

Q3: Can Chinese equipment handle diverse waste streams commonly found in Indian industrial applications?

A: Yes, reputable manufacturers offer extensive customization options, including corrosion-resistant materials and adjustable operating parameters suitable for various industrial waste streams, from textile processing to chemical manufacturing applications.

Partner with Jingjin for Your Multi-Disk Screw Press Requirements

Indian EPC builders and procurement managers who want to find trusted multi-disk screw press suppliers should look into Jingjin's full range of equipment options and engineering services. Our experienced team offers individual advice, thorough technical specs, and cheap quotes that are in line with the needs of your project. We fully back you from the first design to installation and testing. This makes sure that the equipment works well with everything else and performs at its best.

Find out how our tested tools and worldwide service network can make your next EPC project better. If you want to talk about your multi-disk screw press needs and get thorough technical offers that are customized for your uses, email us at [email protected].

References

1. Industrial Wastewater Management in India: EPC Contractor Procurement Strategies and Equipment Sourcing, Journal of Environmental Engineering, 2023

2. Solid-Liquid Separation Technologies for Municipal and Industrial Applications: A Comprehensive Analysis of Chinese Manufacturing Capabilities, Water Treatment Technology Review, 2023

3. Multi-Disk Screw Press Technology: Performance Evaluation and Industrial Applications in Asian Markets, Process Engineering International, 2024

4. EPC Project Management and Equipment Procurement: Case Studies from Indian Industrial Development, Construction Engineering and Management, 2023

5. Chinese Manufacturing Excellence in Water Treatment Equipment: Quality Standards and Global Market Impact, Industrial Equipment Manufacturing Quarterly, 2024

6. Sustainable Wastewater Treatment Solutions for Emerging Markets: Technology Transfer and Equipment Sourcing Strategies, Environmental Technology and Innovation, 2024