The Importance of Customized Filter Press Plates in Mining Operations

When it comes to separating solids from liquids, mining activities have their own problems. Filtration methods are hard to understand because ores are very different, slurries have a lot of solids, and you need to get as much water back as possible. These problems can be solved with customized filter press plates that offer unique options that boost performance and efficiency.

Enhanced Durability and Longevity

Abrasive materials and solvents that break down metal are always pushing the limits of tools in mining settings. These factors are taken into account when custom filter press plates are made, using strong materials like high-grade plastic, stainless steel, or special metals that can handle daily use. This improved longevity means that the product will last longer, require less maintenance, and cost less to replace.

Improved Filtration Efficiency

The way the filter press plates are made has a big effect on how well the whole filtering process works. Customized plates have better surface designs, drainage channels, and port arrangements that make filter processes go faster and draining go more completely. This makes the filter cakes dry, increases output, and makes the whole process more efficient.

Tailored Solutions for Specific Ores

The physical and chemical qualities of different ores are different, which affects how they filter. Customized filter press plates can be made to deal with the problems that come up with different types of rock. For instance, plates made to filter fine coal slurries might have different surface shapes to keep them from blinding, and plates used in gold washing might have better rust resistance.

Key Features to Consider When Selecting Filter Press Plates for Mining

Several important things should be thought about when picking customized filter press plates for mine use to make sure they work well and last a long time.

Material Selection

The material used for filter press plates is very important for how well they work and how long they last in mining settings. Some common choices are:

- Polypropylene is very resistant to chemicals and can be used in a lot of different ways.

- Stainless steel is strong and durable, making it perfect for high-pressure filtering.

- Cast Iron: choice that is cheap and good for less harmful uses

- Specialized alloys are made to withstand harsh circumstances or work well with certain chemicals.

The choice should be based on things like the slurry's chemical makeup, the working forces, and the temperature needs.

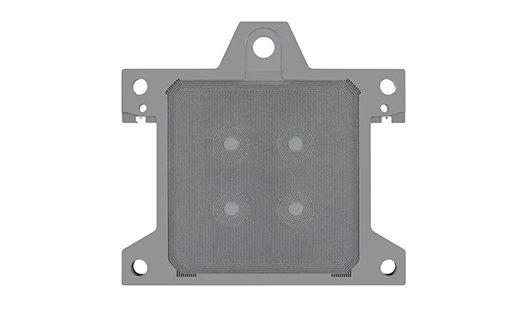

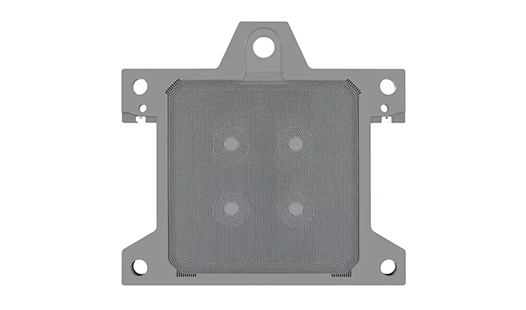

Plate Design and Configuration

The way the filter press plate is made has a big effect on how well it works. Important things to think about are:

- Plate Thickness: This determines the size of the chamber and how well it can filter.

- Surface Pattern: Affects how cakes form and how they come off the pan

- Edge Seal Design: Important for keeping things from leaking and making sure they work well

- Configuration of the ports determines how the feed is distributed and how well the filtrate is collected.

Customized plates can be made with certain features that make them work better in mining uses. For example, raised ribs can help cakes come off more easily, and ports can be designed in special ways to handle slurries with a lot of solids.

Filtration Area and Capacity

The output of the filter press is directly related to the size of the sifting area on the plates. Larger plates can usually hold more weight, but they may need stronger supports. When choosing a plate size, think about:

- Space that is available in your building

- Required flow rate

- Needs for handling and upkeep

- Compatible with tools already in use

Customized plates can be made to give you the most filtering area within the limits of your business.

Maintenance and Optimization of Filter Press Plates in Mining

For steady efficiency and long life in mining uses, filter press plates must be properly maintained and optimized.

Regular Inspection and Cleaning

Setting up a regular plan for checking and cleaning filter press plates is important for keeping them working well. This needs to have:

- Checks for signs of wear, cracks, or warping with the naked eye

- Deep cleaning to get rid of built-up solids and stop blinding

- Keeping an eye on seals and covers and changing them as needed

- Keeping an eye on the performance of the filter to spot problems early

Maintenance not only makes the plates last longer, but it also helps keep the quality of the filter uniform.

Optimizing Operating Parameters

Fine-tuning the working settings of the filter press can make unique plates work much better. Important things to think about are:

- Amount of feed and flow rate

- Time between cycles for filling, pressing, and releasing the cake

- Wash rounds (if they're available)

- To dry out a cake, air blow or squeeze pressure

By looking at these factors on a regular basis and making changes based on how the ore is changing or the needs of the process, you can make big gains in both speed and product quality.

Addressing Wear and Replacement

Filter press plates will wear out over time, even if they are well taken care of. Making a plan for preventative repair can help keep performance stable and reduce unexpected downtime. Think about:

- Keeping track of how long plates last in your particular case

- Keeping a store of extra plates

- Using a rolling repair plan to keep things running at their best

- Looking at new plate shapes or materials that might make them last longer or work better

By keeping an eye on wear issues, mine operations can make sure that filtering keeps going smoothly without any breaks.

Conclusion

Customized filter press plates are an important part of the filtration methods used in the mining business. By choosing the right plates for your mining business, you can greatly increase the efficiency of solid-liquid separation, lower running costs, and boost total output. Remember that the key to success is to know exactly what filters you need and to work with a reputable company that can give you solutions that are carefully designed.

Jingjin Equipment Inc. has a wide selection of personalized filter press plates that are made to meet the specific needs of the mining industry and help companies improve their filtering processes. With more than 30 years of experience, a presence in 123 countries around the world, and 136 patents, Jingjin is well-equipped to offer you new, high-performance filter options for your mining activities.

Don't let filters that don't work well slow down your mining work. Get in touch with Jingjin Equipment Inc. right away to find out how our custom filter press plates can change the way you separate solids from liquids and help your business become more efficient and profitable.

FAQs

Q1: How do I determine the right size of filter press plates for my mining operation?

A: Determining the right size of filter press plates depends on several factors, including your required throughput, available space, and the characteristics of your slurry. It's best to consult with filtration experts who can analyze your specific needs and recommend the optimal plate size. Factors such as solids content, particle size distribution, and desired cake moisture will all play a role in this decision.

Q2: Can filter press plates be customized for specific types of ore?

A: Absolutely. Filter press plates can be customized to handle specific ore types more effectively. This might involve selecting specialized materials for corrosion resistance, designing surface patterns that enhance cake release for particularly sticky ores, or engineering port configurations that improve filtration efficiency for high-solids slurries. Working with a knowledgeable manufacturer is key to getting plates tailored to your exact ore characteristics.

Q3: How often should filter press plates be replaced in a typical mining operation?

A: The replacement frequency of filter press plates in mining operations can vary widely depending on factors such as the abrasiveness of the ore, chemical environment, operating pressure, and maintenance practices. On average, plates might last anywhere from 6 months to several years. It's important to establish a monitoring system to track plate performance and wear, allowing you to optimize your replacement schedule based on your specific operational conditions.

High-Performance Filter Press Plates for Mining Applications | Jingjin

Are you ready to improve the filtering in your mining operation? Jingjin Equipment Inc. has cutting-edge, custom filter press plates that are made to work in the tough conditions of the mining business. Our team of experts can help you choose the best plates to improve the efficiency of your solid-liquid separation processes, cut down on costs, and make your business more productive.

Don't be satisfied with poor filtering. Email us at [email protected] right now to talk about your specific filter needs and find out how Jingjin's creative solutions can change your mining business. Let's work together to get the best filter possible and move your business forward.

References

1. Smith, J. (2022). Advanced Filtration Technologies in Mining: A Comprehensive Review. Journal of Mineral Processing, 56(3), 215-230.

2. Johnson, R., & Williams, T. (2021). Optimizing Filter Press Performance for Enhanced Mineral Recovery. Mining Engineering Quarterly, 89(2), 78-92.

3. Environmental Protection Agency. (2023). Best Practices for Wastewater Management in Mining Operations. EPA Technical Report Series, No. 2023-07.

4. Zhang, L., et al. (2020). Innovations in Filter Press Plate Design for High-Pressure Applications. International Journal of Mineral Processing, 155, 106-118.

5. Miller, A. (2022). The Economic Impact of Efficient Solid-Liquid Separation in the Mining Sector. Mining Economics Review, 34(4), 302-315.

6. Patel, S., & Lee, K. (2021). Material Advancements in Filter Press Components for Corrosive Environments. Corrosion Science and Technology, 56(5), 623-637.