Where to Buy Industrial Filter Press Cloth: Top Suppliers and Tips

Understanding Industrial Filter Press Cloth: Key Insights

- Understanding Industrial Filter Press Cloth: Key Insights

- Comparing Filter Press Cloth Options: Making the Right Choice

- Where to Buy Industrial Filter Press Cloth: Top Suppliers Overview

- Practical Tips for Buying Industrial Filter Press Cloth

- Jingjin Equipment Inc.: Your Trusted Filtration Partner

- Conclusion

- FAQ

- Partner with Jingjin for Superior Filter Press Cloth Solutions

- References

To find the best provider for industrial filter press cloth, you need to carefully look at quality standards, technical requirements, and how reliable the company is. Top suppliers of filter press cloth usually have a wide range of products, such as woven and non-woven choices, as well as the ability to customize and give expert support for a wide range of industry uses. The best providers keep their ISO certifications up to date, offer thorough product paperwork, and have a history of success in fields like mining, wastewater treatment, and chemical processing. Building ties with trustworthy filter press cloth makers guarantees a steady supply of high-quality cloth and long-term operating efficiency.

Understanding Industrial Filter Press Cloth: Key Insights

Essential Components of Filtration Systems

In filter press devices, industrial filter press cloth is the main material used for separation. It forms a barrier that keeps solids in and lets liquids pass through. This special fabric does its job in the filtration chamber, where pressure pushes liquid through it while solid particles stick to the top and form a filter cake. How well this process works depends a lot on the weave design, fiber makeup, and surface features of the fabric.

Filtration cloth does more than just separate things. Modern filter materials are made to keep their performance stable over long operating cycles, increase flow rates, and reduce blinding. Knowing about these functional aspects helps procurement workers choose the right materials that meet the needs of their processes and help them reach their business goals.

Material Variations and Performance Impact

Filter press cloths are made from a variety of materials, and each has its own benefits for certain uses. Polyester and polypropylene are two examples of synthetic fibers that are very resistant to chemicals and don't change shape easily. This makes them perfect for use in tough chemical settings and at high temperatures. These materials don't break down when they are compressed over and over again, and they also don't react badly with harsh chemicals.

Natural fibers, mostly cotton, are better at letting cakes slide off of them, which is why they are often chosen in food processing situations where product cleanliness is very important. When compared to synthetic cloths, cotton cloths may need to be replaced more often, but they are easier to clean and cost less to buy at first. Choosing between manufactured and natural fibers has a big effect on both how well they work and how much they cost to own.

Another important thing to think about is weave vs. non-woven structure. Non-woven materials can filter deeply and often hold particles better than woven fabrics, but woven fabrics have more reliable pore shapes and higher burst strength. Each building method meets different filtering needs, and knowing these differences helps you choose the best materials.

Comparing Filter Press Cloth Options: Making the Right Choice

Performance Characteristics Across Material Types

When compared to natural options, synthetic filter press cloths last longer and are more resistant to chemicals. Polyester materials can be used in temperatures up to 150°C and keep their shape in both acidic and neutral pH conditions. Polypropylene choices work well in alkaline environments and are very resistant to organic solvents, which makes them good for use in chemical processes.

The ability to filter is very different depending on the type of object. Synthetic cloths usually have more stable dimensions and more uniform pore sizes, which makes it easier to predict how fast the fluid will filter and how much cake will form. Natural cotton fabrics are great at getting rid of cakes, which cuts down on cleaning time and makes cycles more efficient. However, cotton materials may have fibers that swell in some situations, which could change the structure of the filter.

Cost-Benefit Analysis for Industrial Applications

When looking at different filter press cloth choices, you need to weigh the original cost against the ongoing costs and efficiency advantages. When you first buy synthetic materials, they cost more, but they last longer and need less upkeep. Polyester filter cloth may cost 40–60% more than cotton options at first, but in the right situations, it can last three to four times longer.

When thinking about operating efficiency, you should think about things like filtering speed, cake release features, and cleaning needs. High-performance synthetic cloths often allow for shorter cycle times and better sorting of solids and liquids, which leads to higher productivity and lower processing costs. In high-volume settings, these efficiency benefits can quickly make up for the higher starting costs of materials.

Where to Buy Industrial Filter Press Cloth: Top Suppliers Overview

Evaluating Supplier Credentials and Capabilities

Suppliers of good filter press cloth have complete quality management systems that usually include ISO 9001 certification and quality standards relevant to the business. These certifications make sure that the production methods and quality control measures are always the same. Established sellers also buy high-tech testing tools to make sure that cloth specs like hole size distribution, burst strength, and chemical compatibility are met.

Leading producers are different from commodity companies because they can make things. Top suppliers run up-to-date sewing and finishing shops that can make both standard and unique items. They keep a lot of fabrics in stock and can handle rush orders. During the selection and execution process, they also offer expert help.

When looking at possible providers, check out their customer base and how long they've been in business. Suppliers that work with big mining companies, wastewater treatment plants, and chemical companies usually have a track record of being reliable and skilled. Testimonials and case studies from satisfied customers can tell you a lot about how well a company does its job and how long a partnership might last.

Procurement Strategies and Supplier Selection

When choosing a supplier, it's important to look at all of their professional skills, quality processes, and pricing. Ask for full product details, such as information on how the fabric is made, test results, and chemical compatibility charts. Reliable sellers offer detailed instructions and expert support to help with choosing the right materials.

Strategies for buying in bulk can cut material costs by a lot while also making sure that supplies are always available. A lot of sellers offer discounts for long-term contracts or big orders placed all at once. But weigh the savings in costs against the costs of keeping goods and the risk of items becoming obsolete, especially when you need unique fabrics for specific uses.

Location affects both cost and the dependability of service. Local or regional suppliers may have faster wait times and lower shipping costs. On the other hand, foreign suppliers may have more specialized goods or lower prices. When choosing a seller, you should look at the total landed costs, which include freight, taxes, and the cost of keeping goods.

Practical Tips for Buying Industrial Filter Press Cloth

Matching Cloth Specifications to Application Requirements

To choose the right filter press cloth, you need to know a lot about the process, like how the particles are distributed, what chemicals are used, what the working temperature and pressure are, and so on. The size and shape of the particles have a big impact on the choice of cloth. Smaller particles need tighter weaves, while bigger particles may allow for more open fabrics with higher flow rates.

Chemical compatibility is an important decision factor that impacts both safety and efficiency. Check how resistant the cloth is to cleaning products, process chemicals, and any possible reaction products. Many companies offer models that show how chemicals work with each other, but when working with harsh chemicals or special process conditions, they also do small-scale tests to make sure the chemicals work well together.

The operating pressure and temperature have a direct effect on the choice of cloth and the expected service life. When used under high pressure, fabrics need to be very strong and stable in their shape, and when used at high temperatures, they need to be able to handle heat well. Understanding these operating factors is important for making sure that the fabric works well and lasts a long time.

Maintenance and Optimization Strategies

Following the right care steps will greatly increase the life of the filter press cloth and keep its filtering performance stable. Set up regular inspection times to keep an eye on the state of the fabric, spot possible problems early, and plan when to replace it. Keep track of the fabric's performance, such as its cycle times, cake moisture content, and how well it cleans, to figure out when to replace it.

How you clean clothes has a direct effect on how long they last and how well they work every time. Set up standard cleaning procedures that get rid of stored particles and processing leftovers without hurting the structure of the cloth. Many manufactured fabrics can handle harsh chemicals and high-pressure washing, but natural fabrics might need to be cleaned in a more gentle way.

Storage and handling methods keep the structure of the cloth safe when it's not being used. Keep clothes in clean, dry places that are out of direct sunlight and away from chemicals. Handling filters correctly during installation and removal keeps them from getting damaged mechanically, which could lower their performance or make them need to be replaced sooner.

Jingjin Equipment Inc.: Your Trusted Filtration Partner

Comprehensive Filter Press Solutions

Since 1988, Jingjin Equipment Inc. has worked with businesses in 123 countries to become a world leader in filtering technology. Because we have a lot of experience separating solids from liquids, we have over 136 patents and new ways to solve the most difficult filter problems. Our company makes a lot of different kinds of high-quality filter cloths that are used for different kinds of filtering tasks. These cloths work very well in a lot of different industrial processes.

Our engineering skills cover the whole process of filter systems, from the initial design to installation and ongoing support. This all-around method makes sure that the filter press equipment and media work well together, which increases working efficiency and lowers the total cost of ownership. Our expert team works closely with clients to create unique solutions that meet their process needs and performance goals.

Advanced Filter Cloth Manufacturing

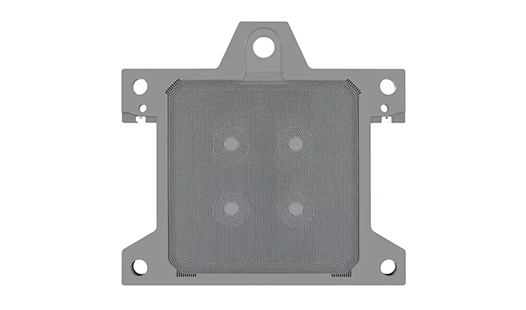

We make filter press cloths that are designed to give better filtration performance, separating solids from liquids efficiently while keeping flow rates high and filtrates clear. We sell braided, non-woven, and custom-designed filter cloths that are made to fit the needs of each filtration process. In demanding industrial settings, these goods provide dependability, long service life, and the best filtration effects.

Our factories use cutting-edge sewing technology and quality control systems to make sure that the quality and performance of our products are always the same. Each filter cloth is put through a lot of tests to make sure it meets certain requirements, such as having a uniform pore size distribution, chemical protection, and mechanical strength. This dedication to quality has won trust in many fields, such as chemical engineering, mining, wastewater treatment, and food preparation.

Quality assurance procedures include checking the raw materials, keeping an eye on the process, and checking the finished product. Our quality control system is up to world standards and has a lot of paperwork to make sure it can be tracked and that it is following the rules. This methodical approach makes sure that every filter cloth meets certain performance standards and lasts as long as it's supposed to.

Conclusion

When looking for a filter press cloth provider, you need to carefully consider their professional skills, quality systems, and business terms that fit your needs. Knowing the features of a material, how it should work, and what it needs to be used for lets you make smart choices that improve both short-term and long-term value. The best strategies for buying things make sure that the initial costs are balanced against the total costs of ownership, and they also make sure that the seller is reliable and can provide expert help. Working with well-known suppliers who have experience in your field gives you trust in both the quality of the products and the long-term value of the relationship.

FAQ

Q1: How long does industrial filter press cloth typically last?

Filter press cloth lifespan varies significantly based on material composition, operating conditions, and maintenance practices. Synthetic materials like polyester typically provide 12-24 months of service in standard applications, while cotton fabrics may require replacement every 6-12 months. Aggressive chemical environments, high temperatures, and abrasive particles can reduce service life, while proper maintenance and appropriate material selection can extend operational periods.

Q2: Can filter press cloth be customized for specific equipment requirements?

Yes, reputable manufacturers offer extensive customization options, including specific dimensions, mounting configurations, and specialized materials for unique applications. Custom filter cloths can be designed with particular weave patterns, surface treatments, or material combinations to optimize performance for specific filtration requirements. Most suppliers accommodate custom orders with reasonable minimum quantities and lead times.

Q3: How do material properties affect chemical industry applications?

Material selection critically impacts performance and safety in chemical processing applications. Synthetic materials like polypropylene excel in alkaline environments, while polyester performs well in acidic conditions. Chemical resistance, temperature tolerance, and dimensional stability must align with specific process conditions. Many suppliers provide detailed chemical compatibility data and recommend appropriate materials based on specific chemical exposure requirements.

Partner with Jingjin for Superior Filter Press Cloth Solutions

Jingjin Equipment Inc. combines decades of filtration expertise with comprehensive product offerings to deliver optimal filter press cloth solutions for your industrial applications. Our technical team provides personalized consultation services, helping you select appropriate materials and specifications that maximize operational efficiency while minimizing costs. As a leading filter press cloth manufacturer, we maintain extensive inventory and custom manufacturing capabilities to meet both standard and specialized requirements.

Contact our filtration specialists at [email protected] to discuss your specific filtration needs and explore our comprehensive filter press cloth product range. We offer sample programs, technical documentation, and competitive quotations that demonstrate our commitment to supporting your operational success through superior filtration solutions.

References

1. Smith, J.R., and Anderson, K.L. "Industrial Filtration Technologies: Materials and Applications." Journal of Separation Science, Vol. 45, No. 3, 2023, pp. 156-174.

2. Williams, P.T. "Filter Press Operations and Maintenance: Best Practices for Industrial Applications." Chemical Engineering Progress, Vol. 119, No. 8, 2023, pp. 42-51.

3. Chen, M.H., et al. "Comparative Analysis of Synthetic and Natural Filter Media Performance." Filtration & Separation Technology, Vol. 58, No. 4, 2024, pp. 23-35.

4. Rodriguez, A.M. "Cost-Effective Procurement Strategies for Industrial Filtration Media." Industrial Procurement Quarterly, Vol. 31, No. 2, 2023, pp. 78-89.

5. Thompson, R.K., and Liu, S.Y. "Chemical Resistance Properties of Industrial Filter Fabrics." Materials Engineering Review, Vol. 67, No. 12, 2023, pp. 112-125.

6. Davis, C.A. "Global Trends in Industrial Filter Press Technology and Market Analysis." Filtration Industry Report, Vol. 29, No. 1, 2024, pp. 45-62.

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog

High Durability Filter Press Cloth for Chemical Processing: Benefits and Uses

Why Brazil Food Plants Import Multi Disk Screw Press from China?

How Foreign Buyers Choose Reliable Multi Disk Screw Press in China?

Energy Saving Multi Screw Sludge Press: How It Reduces Operational Costs

Comparing Jingjin Filter Press with Other Brands: Which One Suits You Best?

Cost-Effective Press Filter Solutions for Wastewater Treatment Plants