Essential Maintenance Tips for Press Filters in Industrial Plants

Understanding Press Filters and Their Maintenance Importance

- Understanding Press Filters and Their Maintenance Importance

- Common Press Filter Maintenance Challenges and Troubleshooting

- Essential Maintenance Tips for Press Filters in Industrial Plants

- Comparing Press Filter Maintenance with Other Filtration Technologies

- Selecting and Procuring Press Filters for Industrial Use

- Conclusion

- FAQ

- Partner with Jingjin for Superior Press Filter Solutions

- References

In workplace settings, keeping Press Filter systems running at their best takes a deep understanding of troubleshooting and preventative maintenance procedures. A Press Filter uses mechanical pressure to separate solids from liquids. It does this by stacking filter plates and cloths to make rooms that effectively remove water from slurries and restore valuable materials. Regular maintenance makes sure that cakes form consistently, stops expensive breaks, and extends the life of equipment while staying in line with environmental rules in mining, chemical processing, and wastewater treatment.

Understanding Press Filters and Their Maintenance Importance

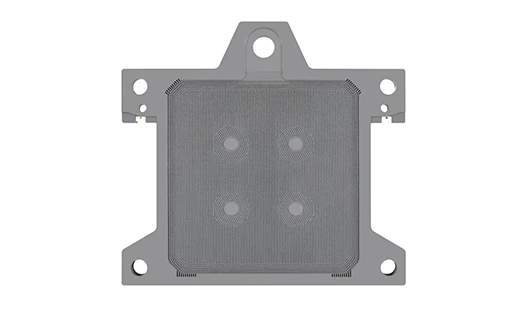

Press filters are important parts of industrial water and wastewater treatment plants because they use mechanical pressure to separate solids from liquids. The basic form is made up of stacked filter plates or frames that are covered with filter cloths. When put together correctly and tightly, these make several chambers. When pressure is put on the filter cloths, liquid moves through them while solid matter builds up on top, creating what experts call "filter cake."

Working Principles and Industrial Applications

Understanding how these filter systems work mechanically is important for how well they work. When slurry goes into the chamber system, hydraulic pressure pushes the liquid through transparent filter media while keeping the solids in place. Dewatering uses in many fields, such as chemical manufacturing, food preparation, mining, and municipal wastewater treatment facilities, work especially well with this process.

These systems are useful for industrial plants because they can handle a lot of material and get a high amount of solids recovery with low running costs. Mining companies use filter presses to handle waste and remove water from concentrates. Chemical companies use them to process paints, dyes, and specialty chemicals. Precision separation is used in the pharmaceutical industry to keep product quality standards high.

Strategic Importance of Preventive Maintenance

Following the right repair procedures will directly affect how well operations run and how long equipment lasts, while also avoiding costly unplanned breaks. Well-kept systems make sure that the quality of the filtering is always the same, use less energy, and keep up with stricter environmental standards. This means that planning for maintenance is no longer a reactive need but a planned goal.

Professionals in procurement and plant management know that organized repair methods protect the value of their investments and make processes more reliable. Regular maintenance keeps small problems from getting worse and turning into major fails that could mess up production plans and make it harder to follow the rules.

Common Press Filter Maintenance Challenges and Troubleshooting

Industrial sites have ongoing upkeep issues that can have a big effect on how well the plant works and how much it costs to run. By learning about these common problems, repair teams can come up with effective solutions instead of just reacting to them.

Identifying Recurring Operational Problems

One of the most common upkeep problems is press filter media wear, which usually shows up as poor cake formation or liquid release that wasn't expected. Problems with the hydraulic system can make the pressure applied not always the same, which can cause the cake to be spread out unevenly and make the separation less effective. When mechanical parts break, especially in support systems and mechanisms for closing, activities can stop completely.

Clogging problems usually happen over time, starting with slightly slower flow rates and then getting worse until they can't handle much more. Cake formation that isn't constant is usually a sign of a problem with the feed, the pressure settings, or the state of the filter cloth. Leakage around plate seals is a sign of wear in important parts that need to be fixed right away to keep the system from getting contaminated.

Structured Troubleshooting Approaches

Systematically observing and writing down working factors is the first step in effective troubleshooting. To set standard performance measures, maintenance teams should keep an eye on pressure readings, flow rates, cake moisture content, and cycle times. Differences from these baselines often show that problems are starting to happen before they become major fails.

Visually checking filter cloths for tears or excessive wear, checking plate surfaces for damage or warping, and trying the hydraulic system's performance through pressure tests are all part of a complete repair plan. Real-life examples from chemical processing plants show that finding pressure problems early on stopped big system failures that could have caused weeks of downtime.

Writing down what you do to fix problems makes useful past data that helps you guess what repairs will be needed in the future and plan the best times to replace things. This organized method gives both repair workers and people who make decisions about purchases the useful information they need to keep things running smoothly and protect the value of the tools they've bought.

Essential Maintenance Tips for Press Filters in Industrial Plants

Using thorough repair procedures guarantees the best performance, increases the life of equipment, and reduces the number of operating interruptions. These basic steps are what make filter system management work well in a wide range of workplace settings.

Routine Inspection and Cleaning Procedures

Visual checks should be done every day to look for clear signs of wear, leaks, or problems with how things are working. As part of the weekly detailed checks, the filter cloth's stability, the position of the plates, and the parts of the hydraulic system are checked. Comprehensive reviews happen once a month and include full system checks, such as pressure tests and measuring performance against known standards.

For thorough cleaning processes, you need to pay special attention to maintaining the filter cloth and getting the plate surface ready. Chemicals used for cleaning must be safe for both the filter media and the things being cleaned. Using the right cleaning methods keeps waste from building up, which can affect later filtration processes, and increases the life of the filter cloth.

Optimal Operating Conditions Management

Keeping the right pressure, temperature, and feed factors lowers the stress on the equipment and increases the efficiency of separation. The operating pressure should stay within the range recommended by the maker. During the filling cycle, the pressure should slowly rise to avoid damaging the cloth or breaking through too soon. Controlling the temperature stops problems with thermal expansion that can make it hard for plates to line up and bond properly.

The features of the feed sludge have a big effect on how well the system works and how much upkeep it needs. Consistent solids content, the right particle size distribution, and the right chemical preparation all work together to make cake formation better while reducing wear on the filter media. Monitoring these factors regularly lets you make changes ahead of time that stop practical problems.

Spare Parts Inventory and Replacement Scheduling

Important extra parts to keep on hand include filter cloths, seals, hydraulic parts, and mechanical parts that wear out quickly. Replacement plans depend on the working conditions, but usually, filter cloth needs to be replaced every 6 to 12 months, depending on how hard the job is. Instead of being replaced at random times, hydraulic seals need to be replaced based on the results of a pressure test.

Automation and tracking systems that work in real time make predictive maintenance possible. These methods help find the best time to repair things while keeping inventory costs as low as possible. Modern monitoring technology can find performance problems before they affect production. This means that planned maintenance can be done during set breaks instead of having to be done quickly during busy times.

Safety Protocol Implementation

When doing maintenance work, it's important to follow strict safety rules that keep workers safe and make sure that rules are followed. Lockout/tagout measures keep systems from turning on by mistake while maintenance is being done. When you wear the right safety gear, you can protect yourself from chemicals, high-pressure systems, and the mechanical risks that come with filter equipment.

When maintaining a press filter, safety training should cover the risks of the hydraulic system, how to handle chemicals safely, and what to do in an emergency. Regular safety checks make sure that rules are being followed and remind everyone in the maintenance group how important it is to take safety precautions.

Comparing Press Filter Maintenance with Other Filtration Technologies

Knowing how to maintain different types of filtration technologies helps engineers and purchasing managers make smart choices based on their budgets, process needs, and practical skills.

Maintenance Intensity Comparisons

In general, press filters need more mechanical upkeep than basic sand filtration systems, but they are better at handling solids and keeping cakes dry. The complicated hydraulic and mechanical systems need skilled workers and a large collection of spare parts, but they work reliably in tough situations where other technologies might fail.

Vacuum filtering systems usually don't need as much mechanical upkeep, but they do cost more in the long run because they need to replace parts more often and may not remove as much liquid. Rotary drum filters have benefits like being able to work continuously, but they need to have their media replaced and cleaning systems checked on all the time. Centrifugal separation technologies use less filter media, but they have fast-moving parts that need to be maintained by people who know what they're doing.

Cost-Benefit Analysis for Technology Selection

To figure out the total cost of ownership, you need to add up the original costs of the equipment, the costs of ongoing upkeep, the amount of energy used, and the reliability of the operation. Even though they require more training at first, press filters often provide better long-term value in situations where high solids recovery and low liquid carryover are needed.

When choosing filtration technology, the comparison study should look at how much upkeep knowledge is available, how easy it is to get spare parts, and how good the service support is. Press filters might work better for places that are good at mechanical repair than for places that aren't as good at it.

Selecting and Procuring Press Filters for Industrial Use

To make good purchasing choices, you need to carefully look at the supplier's skills, the product details, and the long-term service support to make sure that the equipment works at its best for as long as it is used.

Supplier Evaluation Criteria

Reputable makers have a lot of experience with a wide range of industrial uses and have a history of success in similar working conditions. Standardizations for the building of materials, levels of automation complexity, and the ability to customize to meet specific process needs are all signs of a high-quality product.

Technical support includes help with installation, training programs for operators, advice on upkeep, and quick service availability. With global service networks, help is always the same, no matter where the center is located, and the quality of service is the same at all of them.

Product Specification Considerations

Capacity needs for the Press Filter must match the needs of the current process while also being able to accommodate expected growth or changes in operations in the future. The level of automation should meet the level of operator skill and upkeep know-how without making things too complicated or requiring too much training.

Material choices affect both the cost of building something and how much upkeep it will need in the long run. In chemical processing, materials that don't rust are necessary, but normal materials may be enough for local wastewater treatment plants that don't have to handle as much stress.

Post-Procurement Support Requirements

Full installation help makes sure that the system is properly set up and minimizes startup delays and operating problems. Operator training programs should teach basic upkeep processes, routine tasks, and troubleshooting methods that are acceptable for the level of skill of the facility staff.

Maintenance training for facility workers includes rules for preventative maintenance, how to change spare parts, and safety rules that are specific to the equipment that is being used. Ongoing technology support lets you get expert help with difficult maintenance jobs or ways to make operations run more smoothly.

Conclusion

To maintain Press Filter systems well, you need to know a lot about how they work, how to fix problems in a planned way, and how to do proactive preventative maintenance. To be successful, you need to follow strict safety rules, do regular inspections, keep the working conditions at their best, and make sure you have enough extra parts on hand. Spending money on the right maintenance training and practices pays off in the form of longer equipment life, less downtime, and uniform operating performance across a wide range of industrial settings.

FAQ

Q1: How often should Press Filter maintenance be performed?

Regular maintenance intervals typically range from monthly routine inspections to quarterly comprehensive overhauls, depending on operational intensity and process conditions. High-volume applications may require weekly attention, while lighter-duty installations might operate effectively with monthly maintenance cycles.

Q2: What are the most common signs indicating maintenance needs?

Reduced filtration rates, abnormal operating noises, visible filter cloth damage, irregular cake discharge patterns, and pressure inconsistencies indicate immediate maintenance attention requirements. Early recognition of these symptoms prevents minor issues from developing into major operational problems.

Q3: Can Press Filters handle different types of industrial slurries?

Modern Press Filter systems demonstrate remarkable versatility in handling diverse solid-liquid mixtures across mining, chemical processing, wastewater treatment, and food processing applications. Proper system selection and configuration enable effective separation of materials ranging from fine chemical precipitates to coarse mining tailings.

Partner with Jingjin for Superior Press Filter Solutions

Jingjin Equipment Inc. combines over three decades of filtration expertise with innovative technology to deliver reliable Press Filter systems that minimize maintenance requirements while maximizing operational efficiency. Our comprehensive approach includes customized system design, professional installation support, and ongoing maintenance training that empowers your team to achieve optimal performance. As a trusted Press Filter manufacturer serving clients across 123 countries, we provide complete solutions backed by over 136 patents and extensive engineering experience. Contact our specialists at [email protected] to discuss your specific filtration requirements and discover how our advanced systems can enhance your plant's productivity while reducing operational costs.

References

1. Smith, J.A. and Johnson, R.B. "Industrial Filtration Systems Maintenance Protocols and Best Practices." Journal of Industrial Water Treatment, Vol. 45, No. 3, 2023.

2. Williams, M.D. "Comparative Analysis of Solid-Liquid Separation Technologies in Industrial Applications." Chemical Engineering Maintenance Quarterly, Issue 12, 2023.

3. Chen, L. and Thompson, K.R. "Predictive Maintenance Strategies for Press Filter Operations in Mining Industries." Mining Equipment Reliability Studies, Vol. 28, 2023.

4. Anderson, P.L. "Cost-Effective Maintenance Planning for Municipal Wastewater Treatment Filtration Systems." Water Treatment Technology Review, No. 156, 2023.

5. Rodriguez, C.M. "Safety Protocols and Risk Management in Industrial Filtration Equipment Maintenance." Industrial Safety Engineering Journal, Vol. 67, No. 8, 2023.

6. Lee, S.K. and Davis, N.J. "Equipment Selection Criteria for Solid-Liquid Separation in Chemical Processing Plants." Process Engineering Design Manual, 3rd Edition, 2023.

jingjin

Founded in 1988, Jingjin specializes in filter presses and liquid-solid separation solutions, serving over 130 countries worldwide, and is a standard-setter in China's filter press industry.

Get the Filter Press guide

Enter Your Email for Technical assistance for the Filter Press.

Recommended Blog

Where Indian EPC Contractors Buy Multi Disk Screw Press in China?

How Does a Filter Press Work in Wastewater Treatment? A Comprehensive Guide