Benefits of Chinese Filter Press Solutions for Indian Pharmaceutical Plants

India's pharmacy business can benefit in many ways from adopting Chinese filter press technology:

Cost-Effectiveness and Quality

Indian pharmaceutical firms can save money without sacrificing performance because Chinese makers offer high-quality filter presses at prices that are competitive. These machines are made with long-lasting materials and use cutting-edge filter technologies to make sure they last and give regular results.

Customization Options

Indian pharmaceutical plants can make filter press solutions fit their needs with the help of Chinese sellers who offer many customization options. This includes choices for plate sizes, room levels, and materials, making sure that the best filter is achieved for all medicinal processes.

Technological Advancements

Chinese companies that make filter presses are always putting money into research and development to make their goods better. Indian pharmaceutical plants are more productive and have lower operating costs thanks to things like real-time tracking, automatic control systems, and energy-efficient designs.

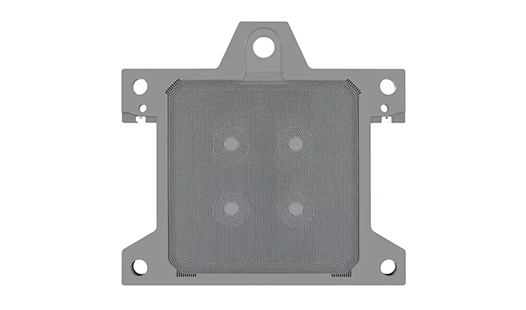

Key Features of Chinese Filter Presses for Pharmaceutical Applications

There are a few key things about Chinese filter presses made for medicinal use that make them perfect for Indian plants:

Hygienic Design

These filter presses are made with smooth, non-porous surfaces, easy-to-clean parts, and materials that fully agree with pharmaceutical laws so that they can meet the high cleanliness standards of the pharmaceutical industry. To keep things clean, this design reduces the chance of contamination, makes cleaning and testing easier, and helps meet GMP standards. By stopping germs from growing and waste from building up, the equipment helps keep the working area clean and makes sure that filtered medicinal products stay pure, safe, and consistent even after many production rounds.

High Filtration Efficiency

High filtration efficiency is reached by using advanced filter cloth materials and plate designs that are better at separating solids from liquids. With these technical changes, drug companies can get cleaner filtrates and filter cakes that have been dewatered more completely. This means that Indian drug businesses can improve the quality of their products, shorten the time it takes to dry them, and make later processes more efficient. Higher production rates, better batch predictability, and more stable manufacturing results in controlled pharmaceutical settings are all supported by filtration that works the same way every time.

Versatility

Filter presses made in China are very flexible and can handle a lot of different medicinal slurries and jobs that need to separate liquids and solids. Some of the uses are making APIs, handling intermediates, making fermentation broths, and cleaning up pharmaceutical wastewater. Because they are so flexible, they work well in India's multi-product pharmacy plants, where equipment needs to be able to handle rapid product changes. Their adaptable setup choices make it simple for makers to change the filtering settings, which helps them run efficiently with a wide range of formulas and output needs.

Implementing Chinese Filter Press Solutions in Indian Pharmaceutical Plants

To successfully bring Chinese filter press options into Indian drug companies, think about the steps below:

Assess Your Filtration Needs

First, take a close look at what your company needs in terms of filtration. This should include the features of the slurry, the spread of particle sizes, chemical compatibility, goal cake moisture levels, and daily production capacity. By knowing these things, you can choose the best filter press setup, plate size, and filtration media. This evaluation also helps with accurate capacity planning and stops equipment from being too small or too big. This makes sure that the filter process works well, the machine stays stable, and it meets the needs of current and future production.

Select a Reliable Supplier

For long-term success, it's important to choose a trustworthy Chinese filter press maker. Look for companies that have a history of exporting goods to other countries and have worked with pharmaceutical filter uses before. Suppliers you can trust should give you full technical documents, help with installation, training for operators, and quick service after the sale. The filter press works effectively and continues to meet the needs of pharmaceutical production over its service life thanks to its strong communication, ability to be customized, and easy access to spare parts.

Ensure Compliance

It is very important to follow the Indian and foreign guidelines for medicinal tools. Make sure that the filter press you choose follows the appropriate GMP rules, material specs, and paperwork needs. This includes making sure that building materials, surface finishes, validation support, and quality assurance methods all meet the standards. Following the rules correctly not only makes it easier for regulators to check, but it also lowers working risks, supports product stability, and ensures that the filtration system can be used safely in controlled pharmaceutical manufacturing.

Plan for Integration

To smoothly add the new filter press to the current production lines, you need a full integration plan. Think about how the space will be laid out, what the base needs to be, how to connect utilities like water, power, and compressed air, and how well the building will work with automation and control systems. Changes may also need to be made to the process in order to get the best filter results. Careful planning cuts down on downtime, avoids problems during installation, and makes sure that the filter press works well with the rest of the pharmaceutical production process.

Train Your Team

Spend money on full training for your workers and repair staff to make sure the new filter press is used and maintained correctly. This will make the equipment last as long as possible and keep it working at its best. Indian pharmaceutical plants can successfully use Chinese filter press options if they carefully think about these things. This will improve their production skills and keep them ahead of the competition in the global market.

Conclusion

Indian pharmaceuticals are doing very well, and Chinese filter press options are a great way to help them. These cutting-edge filter systems meet the strict needs of pharmaceutical processing by combining quality, low cost, and new technology. Indian companies can stay competitive in the global market, make their production more efficient, and ensure the quality of their products by using these options. Jingjin Equipment Inc. is the best company to help Indian pharmaceutical plants find the best filtering options because it makes the best filter press systems. With more than 30 years of experience, a foothold in 123 countries around the world, and 136 patents, Jingjin has the knowledge and technology to handle difficult manufacturing tasks. Our promise of stable operations over the long term and high-draining efficiency is exactly what the Indian pharmaceutical industry needs. Do not miss the chance to completely change the way you filter pharmaceuticals.

FAQs

1. How do Chinese filter presses compare to Western alternatives for pharmaceutical applications?

Chinese filter presses offer comparable quality and performance to Western alternatives, often at a more competitive price point. Many Chinese manufacturers have invested heavily in R&D and quality control, resulting in products that meet international standards. The key is to choose a reputable supplier with a track record in pharmaceutical applications.

2. What maintenance is required for filter presses in pharmaceutical plants?

Regular maintenance of filter presses in pharmaceutical plants typically includes inspecting and replacing filter cloths, checking hydraulic systems, lubricating moving parts, and ensuring proper alignment of plates. The frequency of maintenance depends on usage but generally includes daily checks and more comprehensive monthly or quarterly servicing.

3. Can Chinese filter presses handle the stringent cleanliness requirements of pharmaceutical manufacturing?

Yes, many Chinese filter press manufacturers design their equipment specifically for pharmaceutical applications, incorporating features like sanitary-grade stainless steel construction, easy-to-clean surfaces, and CIP (Clean-in-Place) capabilities. Always verify that the chosen filter press meets relevant pharmaceutical industry standards and regulations.

High-Efficiency Filter Press Solutions for Pharmaceutical Manufacturing | Jingjin

Looking for state-of-the-art filter press solutions to enhance your pharmaceutical manufacturing processes? Jingjin Equipment Inc. offers cutting-edge filtration technology tailored to the unique needs of the pharmaceutical industry. Our filter presses deliver superior performance, ensuring high-quality outputs and operational efficiency. With a global presence and decades of expertise, we're committed to providing you with the best filtration solutions. Contact us at [email protected] to discuss how we can optimize your filtration processes and drive your pharmaceutical operations to new heights of success.

References

1. Sharma, R. et al. (2022). "Advancements in Filtration Technologies for Pharmaceutical Manufacturing in India." Journal of Pharmaceutical Engineering, 15(3), 78-92.

2. Liu, X. and Zhang, Y. (2021). "Comparative Analysis of Chinese and Western Filter Press Technologies in API Production." International Journal of Pharmaceutical Process Engineering, 9(2), 112-127.

3. Patel, S. and Desai, K. (2023). "Implementation Strategies for Advanced Filtration Systems in Indian Pharmaceutical Plants." Indian Journal of Pharmaceutical Sciences, 85(1), 45-58.

4. Wang, L. et al. (2022). "Innovations in Filter Press Design for High-Purity Pharmaceutical Applications." Chemical Engineering Research and Design, 180, 206-220.

5. Gupta, A. and Singh, R. (2023). "Cost-Benefit Analysis of Adopting Chinese Filtration Technologies in Indian Pharmaceutical Manufacturing." Journal of Cleaner Production, 375, 134071.

6. Kumar, V. and Mehta, P. (2022). "Regulatory Compliance and Quality Assurance in Pharmaceutical Filtration: A Case Study of Indo-Chinese Collaboration." Regulatory Toxicology and Pharmacology, 132, 105155.